Tests of EV battery cells manufactured with recycled materials have shown performance comparable to those made with conventional primary materials, UK-based clean technology company Altilium has announced.

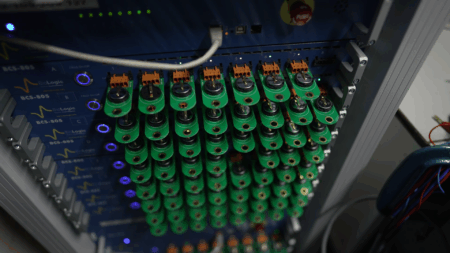

The industrial-scale assembly trials, conducted at the UK Battery Industrialisation Centre (UKBIC) in Coventry, used Altilium’s recycled EcoCathode NMC 811-2036 cathode active material produced at its Devon facilities.

Initial electrochemical testing revealed less than 1% variation compared to commercial benchmarks across key performance metrics, including formation behavior, first cycle loss, impedance, and initial cycling behavior.

The manufacturing process testing also demonstrated that Altilium’s recycled materials could be processed under similar conditions as commercial materials throughout the production cycle, from mixing and coating to formation and testing.

“These results mark a pivotal moment for battery circularity in the UK,” said Dr. Christian Marston, Altilium co-founder and COO. “For the first time, we’ve demonstrated that battery grade EV cells can be manufactured at scale using recycled materials – with no compromise on quality or manufacturability.”

UKBIC’s Chief Technology Officer Richard LeCain added: “This groundbreaking project marks the beginning of a journey that could reduce the UK’s dependence on imported materials and open up a new market for recycled batteries.”

The battery cells will now undergo comprehensive validation with a leading automotive manufacturer. This development comes as the industry prepares for new EU Battery Regulations that will require minimum levels of recycled lithium, nickel, and cobalt in new EV batteries starting in 2031.

Altilium’s proprietary EcoCathode process reportedly recovers over 95% of critical metals from end-of-life EV batteries. The company recently opened its ACT 2 recycling facility in Plymouth and has begun construction of its ACT 3 scale-up plant, which will have capacity to process materials from 24,000 EVs annually.

Previous analysis by Imperial College London indicated Altilium’s recycled cathode active materials showed improvements in purity, morphology, and electrochemical performance compared to commercially available materials, potentially enabling longer battery life, faster charging times, and lower costs.