The rise of electric vehicles has driven the demand for batteries and the materials to produce them, however, raw materials for lithium-ion batteries are becoming more scarce or ethically troubling to extract. One company has claimed to have created the world’s most sustainable battery by being made from a mixture of materials including seawater and wood.

Altris AB has developed a sodium-ion battery cell that claims is not only competitive with lithium-ion batteries, but improves upon it in every key sustainability criteria. The cell also is said to match the performance, life-cycle and energy density of a lithium-ion battery based on a LFP cathode.

The battery, which was produced in partnership with Uppsala cell developer LiFeSiZE and financially supported by the Swedish Energy Agency, is based on Altris’ Fennac – a cathode material that is made up of elements that are widely abundant and have no geo-political sourcing issues: iron, air, seawater and wood. The performance of the material has many similarities with lithium iron phosphate (LFP) in that it has approximately the same voltage and capacity, with no thermal runawayEV. Compared to LFP though, Fennac removes the need to use copper in the battery cell, saving both on weight and cost.

The cell is made up of:

A hard carbon anode made from biomass (from the paper industry or coconut shells), as opposed to mined graphite. Industry standard graphite requires harsh chemical treatments to be used and when the battery is no longer useful, so there is a high likelihood that its stored carbon will be released into the atmosphere. Synthetic graphite alternatives that exist also require tremendous amounts of energy to produce.

A fluorine free and non-flammable electrolyte that is made up of elements available in abundance. Using a fluoride free electrolyte avoids the big problems experienced with the industry standard polyfluorinated carbon chains (PFOS) and LiPF6.

A bio-based binder for the anode and cathode (as opposed to the fluorine-based binders that are standard in lithium-ion batteries).

A water solvent for the cathode and anode coating (eliminating the need for a very energy-consuming handling of the industry standard and poisonous NMP compound).

A cellulose-fiber-based separator, from renewable forestry products (as opposed to the fossil fuel oil-based products commonly used in lithium-ion batteries).

The cell in essence also becomes a carbon sink and when recycled it will not add any CO2 into the atmosphere as any other type of battery would.

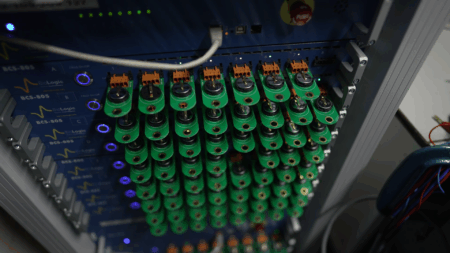

Altris, in partnership with LiFeSiZE, has so far developed 300 mAh cells (which have been cycled more than 100 times) and an 800 mAh cell (which is still undergoing cycle testing).

In the coming months, Altris has said it continues to work with LiFeSiZE to optimize the cell’s cycling parameters, the last stepping stone before producing larger cells. Bigger battery cells will then be produced (up to 10 Ah), with greater energy density (more than 100 Wh/kg) as well as testing the life cycle performance to a commercial level (more than 500 cycles). The cells will also undergo advanced fire testing.

Altris believes that all batteries should enable a renewable future without an increase in cost to the customer or the environment. To this end, Altris is currently collaborating with Swedish, European and Asian partners to introduce this technology to the mass market.