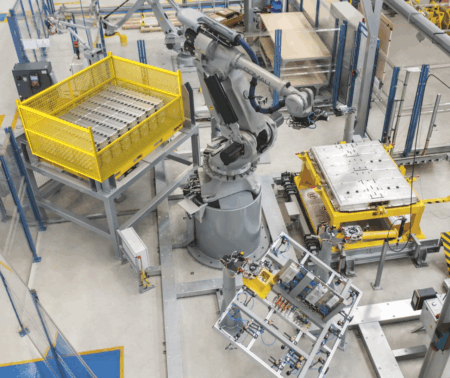

Li-Cycle Corp. a leading lithium-ion battery resource recovery company, has announced it will invest over US$175m in its first commercial lithium-ion battery recycling Hub at Eastman Business Park (EBP) in Rochester, New York.

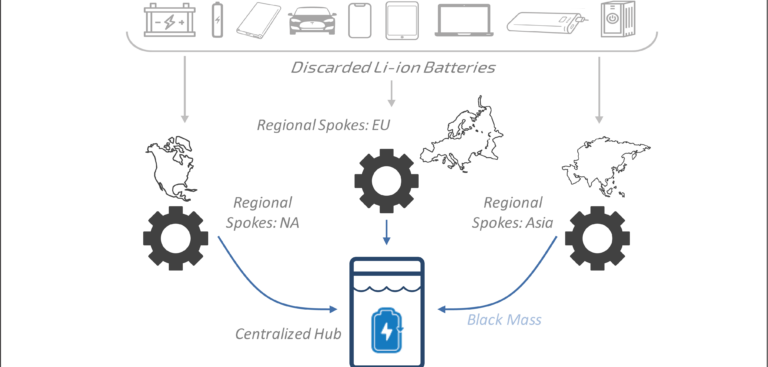

The Hub is a wet chemistry/hydrometallurgical facility that will refine battery-grade materials from ‘black mass’ generated from pre-processing spent lithium-ion batteries and will have the capability of processing material from an equivalent of 60,000 metric tons of spent lithium-ion batteries, roughly equating to 120,000 electric vehicle battery packs. This comes in addition to its Spoke facility that is set to be operational at the park in late 2020 that will produce ‘black mass’ from spent lithium-ion batteries.

Once fully operational, the Hub will be a major producer of battery-grade materials in North America, specifically cobalt, nickel and lithium. This will be the only source of battery grade lithium carbonate in North America and the first commercial facility globally to produce battery grade lithium chemicals from spent lithium-ion batteries. The Hub refines these critical materials from anode and cathode active materials (‘black mass’) while achieving optimal economics and minimized environmental footprint. Together, the Hub and Spoke facilities minimize environmental impact of the end-to-end resource recovery process, and enable a substantially reduced GHG emission intensity when compared to primary production of the same materials.

“We are excited to be able to announce Rochester as the location of Li-Cycle’s Hub refinery,” said Tim Johnston, executive chairman and co-founder of Li-Cycle. “This facility will enable sustainable closed loop production of critical materials for the battery industry, such as cobalt, nickel and lithium, right here in North America supporting the development of electric vehicles and other sustainable energy applications. We appreciate the continued support of the local community, government agencies and Kodak in the development of this project.”

Li-Cycle has previously run a demonstration Hub in Kingston, Ontario to determine key design criteria for the build out of this first Commercial Hub. The company selected EBP as the site for the facility due to the nature of infrastructure available at the site including utilities, logistics and other physical infrastructure. Construction of the Hub facility is set to begin in 2021 and the facility is planned to be fully operational in 2022.

Since inception, the company has developed and validated Li-Cycle’s Hub-and-Spoke technologies – patented, unique and sustainable processes that allow for the recovery of all critical materials found in lithium-ion batteries, capable of producing battery-grade materials such as cobalt, lithium, and nickel at purities required for battery manufacturing. Li-Cycle’s industry-leading processing technology uniquely positions the Company to support the growing international movement towards zero carbon economy and creation of a circular economy for lithium-ion batteries. By providing the same critical materials via resource recovery process, Li-Cycle is committed to minimizing the environmental impact of lithium-ion battery manufacturing.

“As part of Li-Cycle’s global roll-out strategy, the planned facilities in EBP will enable Li-Cycle to leverage its industry-leading technology to foster the development of a closed loop within the robust lithium-ion battery supply chain in the U.S and globally,” said Ajay Kochhar, CEO and Co-Founder of Li-Cycle. “Our team is very excited to be at the vanguard of one of the last and important segments of the electric vehicle and battery supply chains that requires significant development – specifically, how to sustainably handle the incoming ‘tsunami’ of spent lithium-ion batteries. Without sustainable and economically viable lithium-ion battery recycling, it is likely that electric vehicle proliferation will be substantially hindered. Truly innovative and circular battery recycling is the key to providing a solution for this urgent global challenge and opportunity. Li-Cycle is proud of our continued commitment to the sustainable development of a circular economy in the lithium-ion battery value chain. In turn, we are playing a key role in ultimately reducing the cost of batteries and electric vehicles, thereby enabling the mass adoption of electrified transport.”