BMW Group will begin series production of fuel cell systems at its Steyr plant in Austria starting in 2028, marking the launch of the company’s first commercial hydrogen-powered vehicle. The facility is currently preparing for manufacturing of BMW’s third-generation hydrogen drive system, with prototypes already being built at competence centers in Munich and Steyr.

“The launch of the first-ever fuel cell production model from BMW in 2028 will add another exceptionally efficient high-performance drive system with zero emissions to our technology-open product portfolio,” said Joachim Post, Member of the Board of Management of BMW AG, Development. “The choice of Steyr as the production location clearly demonstrates our commitment to a European innovation footprint.”

The new fuel cell system represents a significant advancement over previous generations. BMW’s first-generation system, used in the BMW 535iA in 2014, was supplied entirely by Toyota Motor Corporation. The second generation, currently used in the BMW iX5 Hydrogen pilot fleet, featured a BMW-developed overall system with individual fuel cells from Toyota.

For the third generation, BMW and Toyota are jointly developing the powertrain system for passenger vehicles, with the core fuel cell technology creating synergies for both commercial and passenger vehicle applications. The collaboration allows both companies to leverage development and procurement synergies while maintaining brand-specific models.

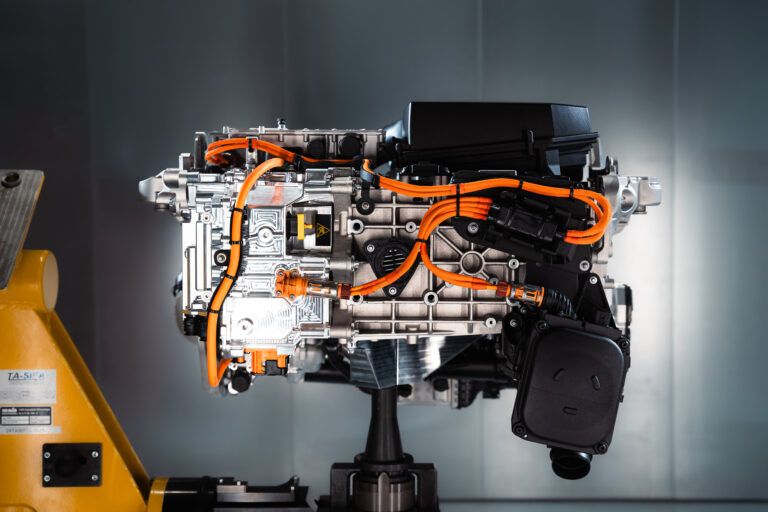

The new system offers several improvements over its predecessor. The fuel cell system’s footprint has been reduced by approximately 25 percent through increased power density, enabling more compact construction. The third generation can be integrated into future vehicle architectures, supporting BMW’s technology-open approach for offering various drive system variants.

Efficiency improvements come through upgraded component parts based on jointly developed drive technology with Toyota and improved operating strategies. These advances result in increased range and output with lower energy consumption compared to the second generation.

BMW Group’s Munich competence center for hydrogen is currently producing prototypes of the fuel cell systems. The systems comprise fuel cells and all components needed for efficient operation, including cooling systems and hydrogen and air subsystems.

BMW Group Plant Landshut will manufacture key components, including the hydrogen-specific BMW Energy Master, which controls power supply across 400-800V ranges and interfaces with high-voltage battery data. Construction of new hardware and equipment for the Energy Master will begin in late May 2026, with prototype production starting mid-2026 at BMW Group Plant Dingolfing.