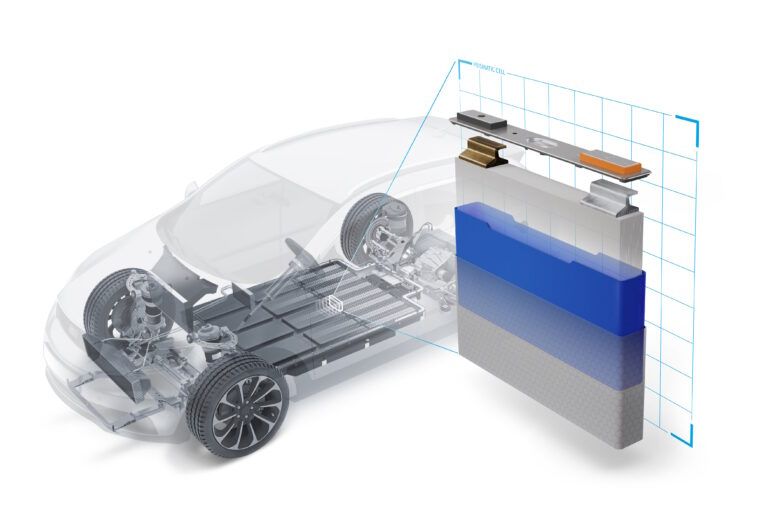

Freudenberg Sealing Technologies has introduced two products aimed at enhancing the performance and safety of EV batteries: nonwoven cell envelopes and custom-designed cell caps.

The new nonwoven cell envelopes offer significant advantages over conventional films used in battery cell stacks. These envelopes consist of a fiber network with an ultra-homogeneous pore structure, providing improved electrolyte wettability and reduced risk of gas bubble entrapment during cell filling. The material also enhances heat management within the cell and creates an additional electrolyte reservoir, addressing key challenges in battery technology.

Complementing the cell envelopes, Freudenberg has developed custom-designed cell caps in collaboration with cell manufacturers. These caps integrate essential functions, including rupture disks for gas dissipation in case of thermal runaway.

“We combine state-of-the-art materials with intelligent design and merge our expertise in sealing technology and engineering plastics with our knowledge of stamping technology,” said Giulia Richard, Global Marketing Director at Freudenberg Sealing Technologies. “This allows us to set new standards to ensure perfect sealing and a long cycle life for the cell caps.”

The cell caps are designed to be gas-tight throughout the battery’s lifecycle, ensuring optimal performance under various operating conditions. They also offer exceptional mechanical resistance and compatibility with different electrolytes and coolants.

“Mobility is changing, and Freudenberg Sealing Technologies is staying ahead of the curve,” said Ulrich Huth, President Automotive Sales at Freudenberg Sealing Technologies, “As the market leader in the technology, quality and service segments for the automotive sector, we have all the expertise necessary to develop and manufacture innovative and leading-edge products for the mobility of the future.”

These innovations, claim Freudenberg Sealing Technologies, represent significant advancements in electric vehicle battery technology, potentially leading to improved safety, performance, and longevity of electric vehicles.