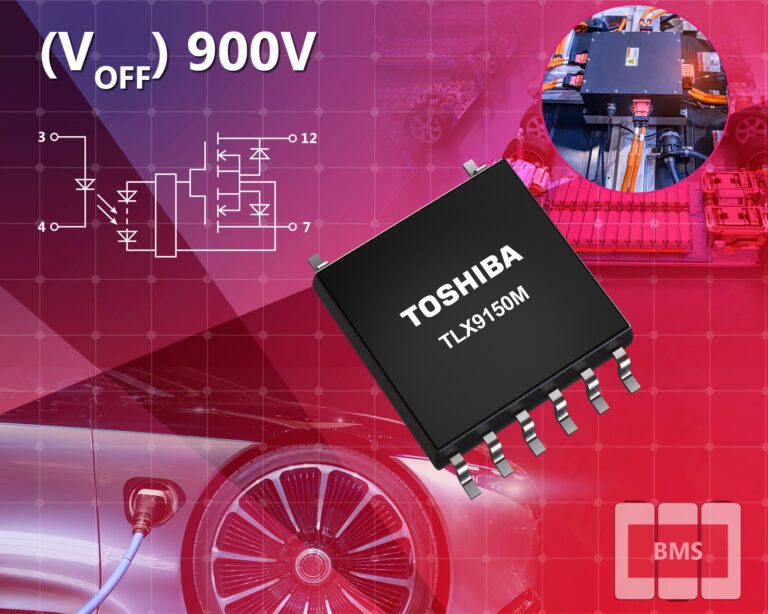

Toshiba Electronics Europe has announced a breakthrough in automotive battery control technology with the launch of the TLX9150M, a high-voltage transistor output photorelay designed specifically for 400V electric vehicle battery systems.

The new device which the company says represents a significant advancement in battery management system (BMS) technology, features a robust 900V minimum breakdown voltage and responds within one millisecond, crucial for critical safety functions such as voltage monitoring, mechanical relay failure detection, and ground fault identification in electric vehicle batteries and fuel cell systems.

“The TLX9150M marks a significant step forward in automotive battery management technology,” said Johannes Bauer, Product Marketing Manager at Toshiba Electronics Europe. “Its combination of high performance and compact size addresses the growing demand for more efficient electric vehicle components.”

The device’s innovative design incorporates an infrared LED coupled with a photo-MOSFET, creating a secure electrical isolation barrier between control and switching circuits. Operating with a trigger current exceeding 3mA, the relay achieves remarkable energy efficiency, drawing only 100nA during inactive periods at ambient temperature.

Packaged in Toshiba’s new SO12L-T housing, measuring just 7.76mm × 10mm × 2.45mm, the device is 25% smaller than its predecessor while maintaining pin compatibility for easy integration. The design meets stringent automotive standards, including AEC-Q101 qualification and IEC 60664-1 compliance, with reliable operation from -40° to +125°C.

Industry analysts suggest this development could significantly impact EV manufacturing, potentially reducing costs while improving safety and efficiency in high-voltage battery systems.