The integration of mass spectrometry for gas evolution analysis in battery thermal runaway

The growing demand for high-energy lithium-ion batteries has highlighted safety concerns due to thermal runaway incidents, which can lead to fires and explosions. These events occur when exothermic reactions within result in heat accumulation, triggering decomposition reactions that release flammable gases and oxygen, creating hazardous conditions.

As the temperature in the battery temperature increases, a cascade of complex reactions may take place. Lithium salt decomposition begins above 70°C, followed by the breakdown of the Solid Electrolyte Interphase (SEI) at 90-130°C, releasing gases like C₂H₄ and CO₂. Electrolyte decomposition accelerates up to 230°C, releasing fluorinated compounds. Cathode materials decompose at 200-300°C, releasing oxygen. By 235°C, full-scale thermal runaway occurs, generating gases such as CO₂, CO, H₂, CH₄, and HF, alongside vaporized electrolyte components, further intensifying combustion risks.

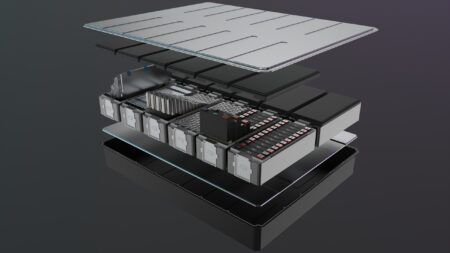

HEL Group’s BTC-500 adiabatic calorimeter enables comprehensive thermal behavior analysis, evaluating the response to thermal, electrical, and mechanical stress in the battery. Here we investigate the gas evolution profiles of two lithium-ion batteries using a combination of adiabatic calorimetry (BTC-500) and mass spectrometry.

The test

Two lithium-ion batteries were tested, one with a 151 Ah capacity and another with 177 Ah, both at 100% state-of-charge (SOC). A high-pressure mass spectrometer (Pfeiffer) was integrated with the BTC-500 calorimeter to analyze gas evolution during thermal runaway. This setup enabled real-time monitoring at high frequency (50 ms per mass unit), high pressure (8 bar), and high temperature, ensuring rapid detection of transient chemical reactions (Fig 1). Using a Heat-Wait-Search (HWS) protocol, batteries were heated incrementally until they entered thermal runaway. In-situ gas analysis was conducted in real-time, while periodic online sampling allowed further assessment. Post-runaway gas collection enabled retrospective analysis of transient species.

The gas composition analysis showed distinct profiles for each battery (Fig 2). The 151 Ah Battery produced large amounts of CO₂, H₂, CH₄, C₂H₄, and CO, alongside with minor traces of SO₂ and mercaptamines. While the 177 Ah Battery released significant CO, CO₂, and H₂, with small amounts of toluene, trimethylamine N-oxide, and long-chain hydrocarbons. The differences in gas composition highlighted how differences in electrolyte composition and electrode materials influence thermal runaway behavior and gas composition.

There are limitations of conventional gas analysis as while gas chromatography (GC) is widely used it generally operates at low pressures and temperatures, making it unsuitable for the study of gas evolution under thermal runaway conditions. Additionally, GC requires off-line sampling, which may result in the loss of volatile species.

The BTC-500’s integration with mass spectrometry allows for real-time, high-frequency gas analysis under high-pressure and high-temperature conditions. This approach is necessary to understand rapid reaction dynamics accurately. By combining BTC-series calorimeters with high-pressure mass spectrometry, HEL Group has introduced an advanced analytical solution that enhances battery safety research. This assembly allows researchers to track reaction pathways with millisecond precision, providing deeper insights into gas generation mechanisms.

The conclusion

HEL Group’s BTC-500 was successfully integrated with a mass spectrometer, enabling real-time, high-resolution gas evolution monitoring during lithium-ion battery thermal runaway. The combination of both systems enhances safety research by providing extra insights into gas generation processes. This helps can help to improve the design batteries yielding safer units. Understanding gas emissions during thermal runaway events is fundamental to create accurate risk assessments and put efficient mitigation strategies in place, contributing to the safer implementation of lithium-ion batteries in critical applications.

helgroup.com