History shows that if a commodity has enough value, we’ll find a way to source it – and we’ll make the price work for us too.

Right now, a fierce debate is raging over the price volatility of rare earth materials, used for magnets in certain types of electric motors – so much so that many people are dismissing the magnet motor as the future.

As a maker of such an electric motor, you won’t be surprised to find I strongly disagree. But raw material price isn’t the whole story and, when it comes to commodities, there’s an important lesson from the past people seem to be forgetting.

Back in 1973, the oil crisis led to drastic efforts to wean ourselves off the black stuff with giants like General Motors even going to great lengths to get an electric car into production (raise your hand if you remember the Chevette-based Electrovette).

The reality, though, was that 1970s EV technology was very poor and gasoline-powered cars were a whole lot better, so we learned to live with higher pump prices. In fact, that led to more exploration, reducing the price of oil.

Fast forward to 2018 and we’re at a real turning point in the automotive industry. Electrification is the future – whether it’s pure electric vehicles, hybrids or range extenders – and there is more focus than ever on electric powertrain components. And how much these cost.

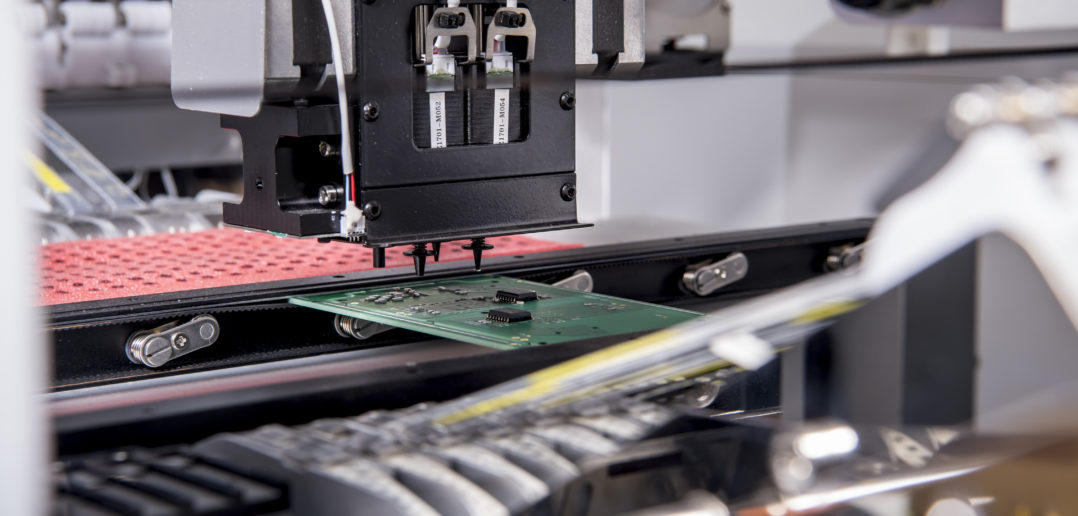

Equipmake’s APM200 motor uses rare earth Neodymium magnets and, yes, the raw material cost is high (as much as 50% of the entire motor), but that’s not the whole story. The cost of processing Neodymium is actually low and once you take into account the cost of making the motor, magnets make up just 15% of the processed bill of materials.

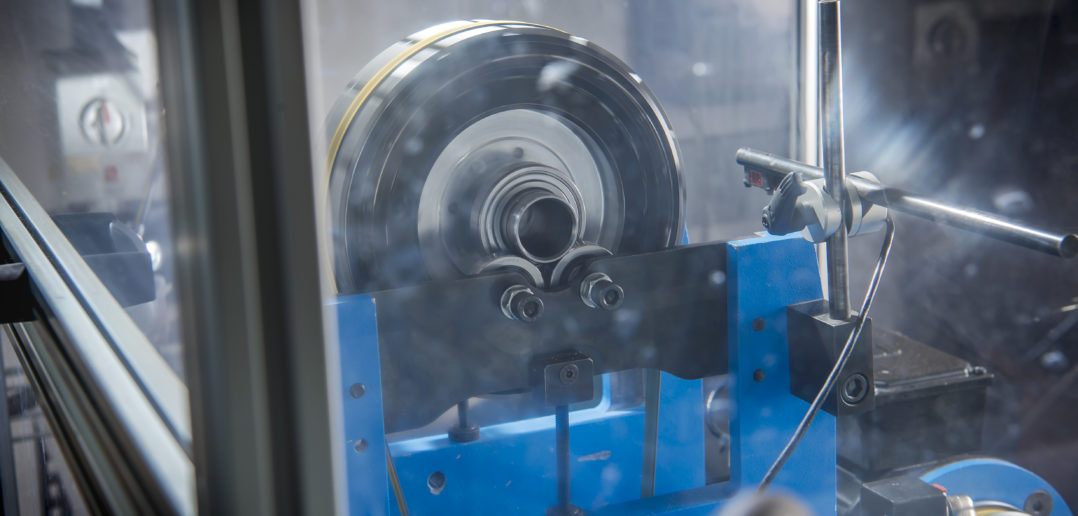

Magnet motors also have many advantages. Our APM200 motor is what’s called a spoke motor: it has the magnets arranged around the rotor like the spokes of a wheel, which allows us to make the best use of the magnetic flux and get coolant very close to the base of the magnet, keeping them cool. As a result, we can run the motor harder for longer and use the least amount of parts too.

It is small and efficient and the cost (and effect of price volatility) is minimized because we are getting the most out of the magnets. Motors without magnets are larger and heavier because they use much more copper and steel in their construction, which are two materials that are still highly variable in price. They’re also a lot less efficient too.

There is another way of looking at this: batteries are still by far the highest cost of the entire electric powertrain. So if your electric motor is lighter, more powerful and more efficient, you can use a smaller battery pack to get the same range, further offsetting magnet cost.

Given all this, where is electric motor design heading? Well, Equipmake is not alone in believing the future is magnet motors: you only have to look at Tesla.

The Model S and Model X use non-magnet induction motors, but the Model 3 – the car designed to take the brand to the mass market – uses a magnet motor. That’s a significant change of direction.

While most of the magnetic material used in electric motors is sourced in China, if history has taught us anything, if it becomes a big enough issue, other sources will be found.

And we’ll make the price work for us too, of that there is no doubt.

About the author

Ian Foley is the managing director of Equipmake, whose APM200 electric motor was developed for the Ariel Hipercar.