Hydrohertz launches Dectravalve, a patented multi-zone battery cooling system that reduces EV fast-charging times by up to 68% while improving range, lifespan and safety through precise temperature control

Hydrohertz has launched what it claims is a world-first battery cooling technology that could reduce EV fast-charging times by up to 68 percent while extending battery life and improving safety.

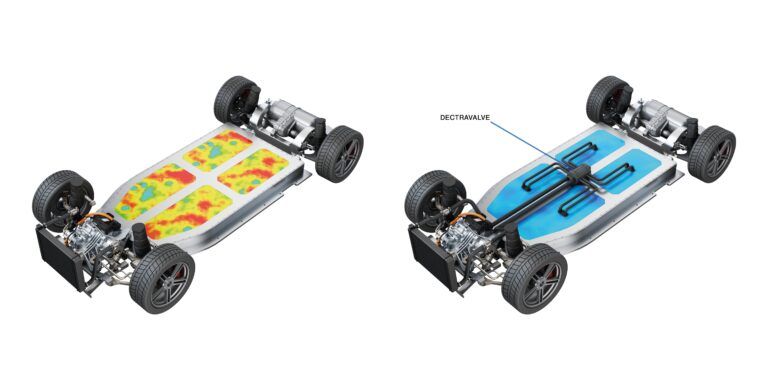

The company’s patented Dectravalve system uses intelligent multi-zone valve technology to precisely control temperatures across different parts of an EV battery pack, rather than treating it uniformly like conventional systems.

“Optimising the operating temperature of an EV battery is crucial to both its short- and long-term performance,” says Hydrohertz CTO Martyn Talbot. “Unlike traditional systems which treat the entire pack uniformly, the Dectravalve allows for targeted heating or cooling of individual modules within the battery.”

In testing conducted with Warwick Manufacturing Group, a 100kWh lithium iron phosphate battery equipped with Dectravalve maintained its hottest cell below 44.5°C with only a 2.6°C temperature difference across the entire pack during ultra-fast charging.

This contrasts sharply with typical fast-charging conditions where peak cell temperatures can reach 56°C and temperature variations exceed 12°C. When cells surpass 50°C, charging power must be reduced to prevent lithium plating and long-term damage, significantly extending overall charge times.

The Dectravalve-equipped battery remained in what the company calls the “optimum high-power zone” throughout testing, with every module performing at peak efficiency.

“In our testing, we kept battery cells within just 2-3°C, which translates directly into faster charging, longer battery life, and critically, enhanced safety,” says Talbot.

According to Hydrohertz, the technology could reduce a typical 30-minute charge on a 350kW fast charger to approximately 10 minutes, bringing EV charging times close to conventional refuelling. The system could also deliver up to 10 percent more real-world driving range by maintaining optimal cell temperatures during all operating conditions.

“The Dectravalve solves a fundamental problem of EV battery thermal management systems – how to achieve true independent zone control of temperature without the complexity, weight, and energy waste of multiple valve arrays,” Talbot says. “Our innovation is elegantly simple: a single, digitally controlled unit that can manage four or more cooling zones separately.”

The system works by creating independent cooling loops for each zone, preventing warm coolant from leaking between zones and avoiding what Talbot described as a thermal ‘domino effect’ where hotspots spread across the pack.

Safety improvements are significant, with maximum cell temperatures capped to prevent overheating and minimize risks of lithium plating and thermal runaway. The technology also extends battery life by reducing strain on individual cells.

The system is chemistry-agnostic and can work with any current or future battery technology. Hydrohertz says it offers a cost-effective solution compared to developing entirely new battery packs, while also potentially boosting residual values of used vehicles and enhancing second-life applications for battery packs.