Protean Electric, a UK-based in-wheel motor technology company, has announced that its latest generation ProteanDrive system will enter production in 2026, marking a significant development in EV powertrain technology.

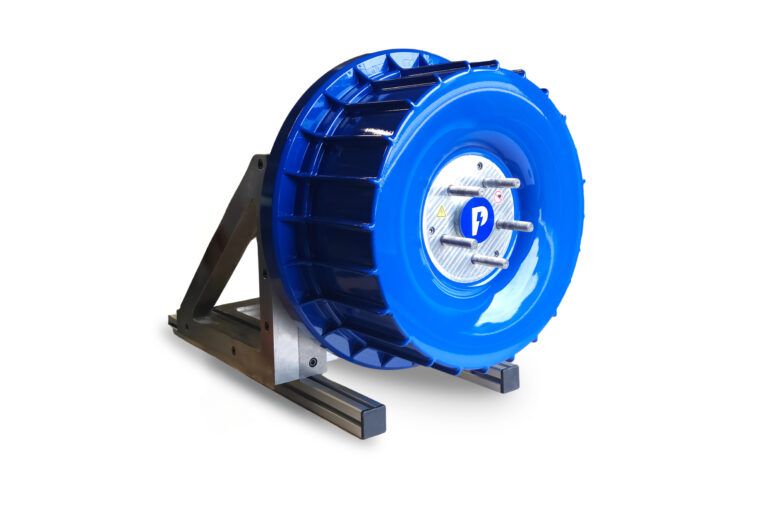

The company, which operates from facilities in the UK, China, and Turkey, claims its new Pm18 2500 in-wheel motor system has achieved cost parity with traditional twin e-axle solutions while offering additional vehicle manufacturing savings.

The Pm18 2500 system delivers over 2,500Nm of torque and 220kW of power per wheel motor, enabling vehicles to accelerate from zero to 100km/h in approximately three seconds. According to Protean, this represents the first instance of an in-wheel motor displacing a twin e-axle setup based on cost considerations rather than purely performance benefits.

The technology eliminates traditional driveline components and reduces manufacturing complexity, potentially offering automakers two key advantages: easier integration into existing vehicle platforms and, for new designs, improved modularity and space efficiency.

“We have always believed that in-wheel motors make better EVs, and we are able to prove that today,” said Andrew Whitehead, CEO of Protean Electric. “In this industry better must also mean cheaper, without sacrificing quality or performance. As twin e-axle systems become commonplace, we have shown we can displace them with our ProteanDrive solutions, to deliver cost-effective solutions offering more customer value.”

Protean’s development follows years of evolution in the EV sector. The company traces its origins to PML Flightlink, which gained attention in 2006 by fitting four in-wheel motors to a Mini Cooper, creating a 640bhp vehicle with sub-5.0-second acceleration to 62mph. The technology was later acquired by NEVS before being taken over by EV specialist Bedeo in 2019.

Currently, Protean operates with approximately 120 employees across four global locations: an engineering center in Farnham, UK; a factory in Tianjin, China; a supply chain office in Shanghai; and a production facility in Istanbul. The company produced 1,500 motors last year, with roughly one-third supplied to parent company Bedeo for van conversion applications.

The company will demonstrate its latest ProteanDrive technology at the IAA Mobility show in Munich from September 9-12, 2025, at Hall A3, Stand B01. This follows Protean’s recent recognition with an Innovation Award at the Autocar Awards, acknowledging the potential impact of in-wheel motor technology on future electric vehicle design and manufacturing.

The technology represents a shift toward more integrated electric powertrains, potentially influencing how automakers approach electric vehicle architecture and manufacturing processes.