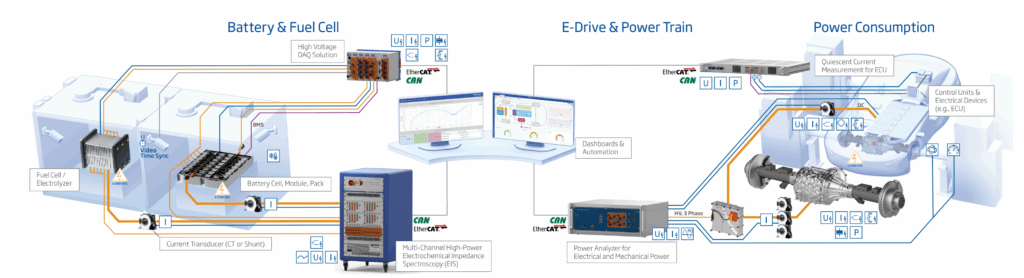

From battery safety to powertrain Validation – solving today’s testing challenges with scalable, high-accuracy DAQ solutions

EV testing is evolving—are your measurement systems keeping up?

The shift to electric mobility is pushing the boundaries of battery performance, powertrain efficiency, and end-of-line validation. Engineers and manufacturers are under increasing pressure to improve safety, enhance energy efficiency, and reduce production costs, all while dealing with higher voltages, complex energy storage systems, and increasingly stringent testing requirements.

These challenges demand a new generation of test and measurement solutions—ones that go beyond standard DAQ systems to deliver real-time insights, seamless integration, and industry-leading accuracy across a range of test environments.

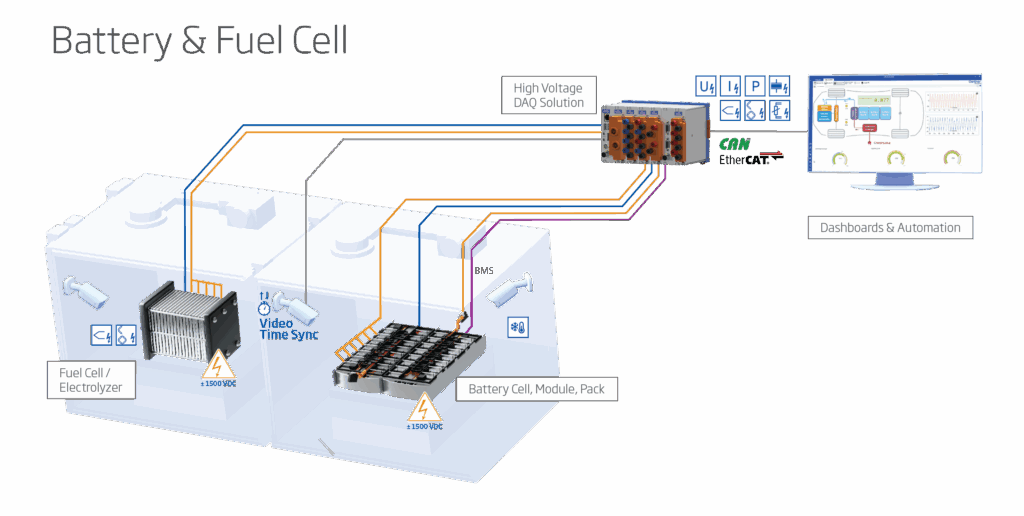

Battery abuse testing needs more than just data—it needs visual proof

Battery failures can happen in milliseconds during penetration or short-circuit testing. Whether it’s a thermal runaway event or mechanical deformation, identifying the exact location requires more than just numerical data—it requires real-time, synchronized measurements with high-speed data acquisition.

HV data acquisition solutions

HV data acquisition solutions

Our high-speed HV DAQ sy stems integrate seamlessly with video recording, ensuring that every frame is time-synchronized with electrical, thermal, and mechanical measurements on potentials up to 1500 VDC. With best-in-class noise performance and sampling rates of up to 4 MHz, engineers can capture critical events with absolute precision. The system operates remotely and fully synchronized, ensuring that even complex multi-channel test setups remain accurate and reliable under extreme testing conditions. Powerful data archiving and intelligent compression allow for long-duration testing while maintaining high-resolution data integrity.

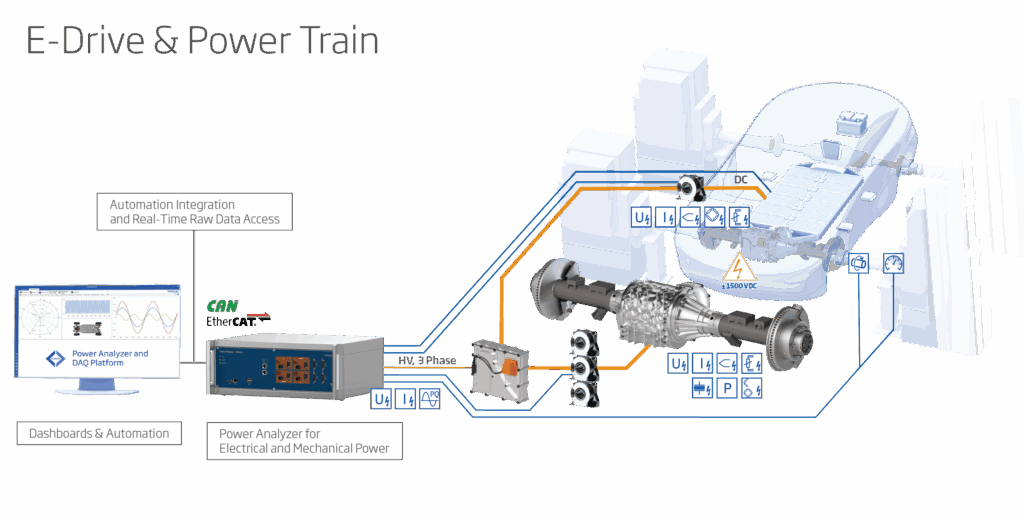

Powertrain efficiency is only as good as the data behind it

As technology advances, EV powertrains operate at higher voltages and faster switching frequencies. Traditional power analyzers struggle to deliver accurate measurements with sufficient signal-to-noise ratio and low distortion across inverters, motors, and batteries, leading to missed efficiency optimizations.

Power analyzer for seamless test bed integration

Power analyzer for seamless test bed integration

Our GPA100 Power Analyzer delivers real-time electrical and mechanical power analysis with ultra-low noise floor performance and a 4 MHz sampling rate per channel—the best in its class. Featuring intelligent data compression and high-speed EtherCAT integration, it provides triggered data logging and direct access to raw values, ensuring instantaneous insights for optimizing powertrain efficiency. With open interfaces supporting various protocols, the GPA100 is designed for seamless integration into test benches and end-of-line production environments. Its intuitive software and compatibility across multiple operating systems make it a versatile solution for R&D and large-scale validation.

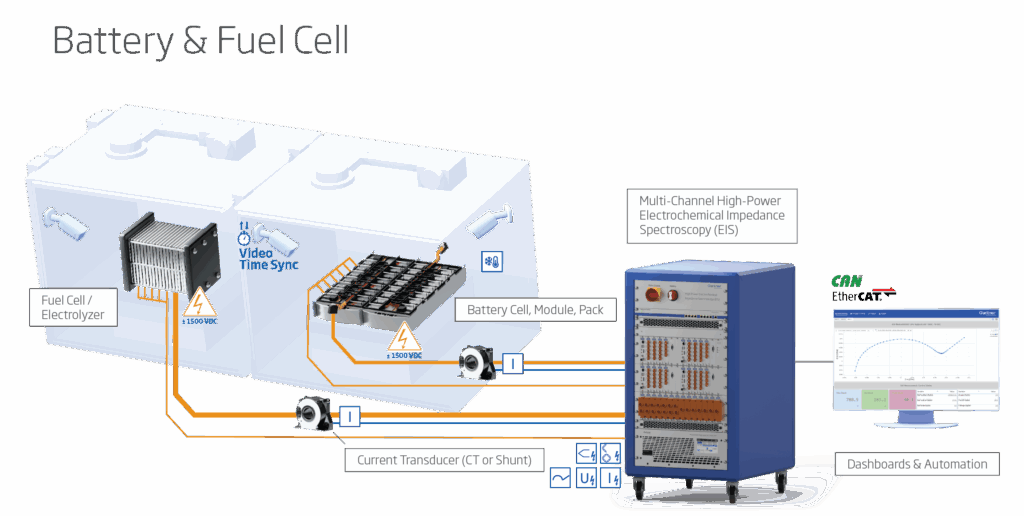

EIS at every level – cell, module, and pack

Battery technology isn’t just evolving—it’s diversifying. From solid-state cells to high-capacity packs, each new design brings unique challenges in voltage monitoring, impedance analysis, and thermal behavior. Many DAQ systems struggle to scale, forcing engineers to use multiple platforms for different testing stages, creating integration headaches and data inconsistencies.

The Gantner EIS system

The Gantner EIS system

Our EIS solution provides a single, scalable platform that can adapt to battery testing at every level—from individual cells to full packs. With remote and synchronized measurement capabilities, engineers can track battery aging and performance degradation in real-time, even under full charge or discharge conditions. This system is fully synchronized with additional temperature, strain, and voltage measurements, ensuring a comprehensive analysis of battery behavior. Built with powerful data archiving and intelligent compression, it enables long-term tracking of battery characteristics, supporting predictive maintenance and degradation modeling. The system’s open interfaces and support for multiple communication protocols ensure easy integration with third-party hardware and software.

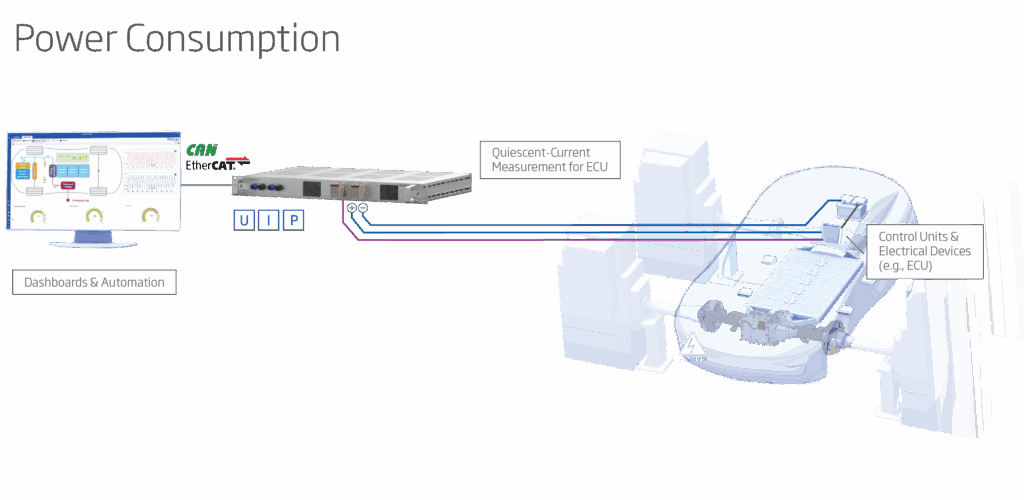

Current measurement – detecting the hidden battery drain

Current measurement – detecting the hidden battery drain

EV batteries don’t just lose power on the road—they lose energy when parked. Modern electric vehicles rely on hundreds of ECUs, sensors, and electronic subsystems that continue drawing power in standby mode. Over time, these low-level power drains reduce battery longevity, shorten vehicle range, and increase warranty concerns for automakers. Many traditional measurement systems lack the resolution and real-time capabilities needed to detect power consumption in the microampere range, making it difficult for engineers to identify and eliminate unnecessary losses.

Solutions for breadboard testing

Our Quiescent Current Measurement System delivers ultra-low current detection with microampere (µA) precision, enabling engineers to profile standby power consumption and optimize vehicle electronics accurately. The system runs in real-time on any OS, ensuring seamless integration into both lab-scale testing and large-scale production environments. Designed for fully automated end-of-line testing, it features open interfaces and intelligent data compression, allowing engineers to analyze long-term trends while minimizing storage requirements. The synchronized, remote operation capability ensures high accuracy even in distributed test setups, helping manufacturers meet stringent efficiency and compliance targets.

Future-proof your EV testing with Gantner Instruments

Future-proof your EV testing with Gantner Instruments

Testing requirements are getting tougher, and measurement systems shouldn’t be the weak link. Our modular DAQ solutions are designed to capture every critical data point without compromise, offering scalable architectures, remote synchronization, and seamless integration with existing test environments. Whether you’re pushing the limits of battery durability, fine-tuning powertrain efficiency, or ensuring flawless production quality, Gantner Instruments provides the tools and technology to keep you ahead.

With intuitive software interfaces, real-time analytics, and powerful data management, our systems simplify the complexity of EV testing while delivering unmatched accuracy, resolution, and flexibility. Our open interfaces and support for various protocols ensure that Gantner solutions integrate easily into your existing infrastructure, keeping your test systems future-ready and adaptable to new testing standards and methodologies.