A new solution has been developed to help prevent water condensation and potentially leaking coolants inside lithium-ion battery packs causing function and lifetime damage.

Battery Pack Liquid Absorbers created by Freudenberg Performance Materials are absorbent pads that capture and store unwanted liquids. With adjustable absorption capacity and custom geometries, Battery Pack Liquid Absorbers help ensure long-lasting battery packs.

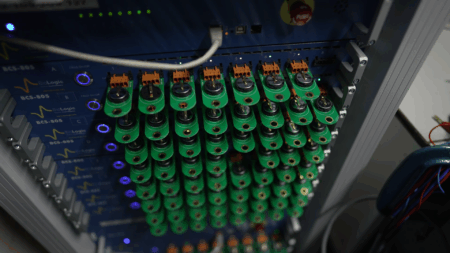

Battery packs are the core elements of mobile and stationary lithium-ion energy storage systems in automotive and industrial applications. The performance and lifetime of these components are largely responsible for the efficiency of the energy storage system. Moisture and liquids occurring inside the packs can considerably damage them. Here, the humidity of the air is one major issue. Air enters into the battery pack and creates condensation inside the cooled pack. Another problem is coolants which may accidentally leak out of the cooling system. In both cases, Freudenberg´s Battery Pack Liquid Absorbers act as a safety system to reliably capture and retain condensate and leaking coolants.

Freudenberg´s Battery Pack Liquid Absorbers are absorbent nonwoven pads endowed with fast liquid take-up and high retention capacity. Even in an emergency, leaking coolants are quickly absorbed and reliably retained. The modular design of the pads allows for scaling of the absorption capacity, which is limited only by the available space. Customer-specific geometries can even be implemented thanks to the flexible material.

“As liquid-cooling systems are prevailing to deliver efficient thermal management for high power batteries, we believe that our Battery Pack Liquid Absorbers will become a must-have safety component of future high-voltage systems,” said Thomas Petzel, general manager of Freudenberg Performance Materials.