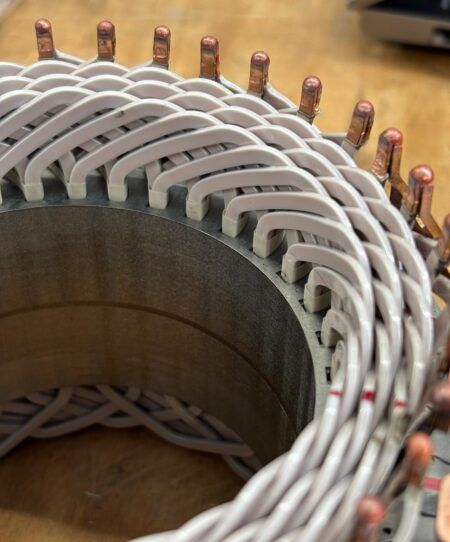

Swiss electrical measurement specialist LEM has introduced a current sensing component that combines shunt and Hall effect technologies in a single unit for EV battery management systems (BMS). The Hybrid Supervising Unit (HSU) represents the first commercial product to integrate both measurement technologies, according to the Geneva-based company.

The device addresses requirements for compact design, cost reduction, and safety compliance in high-voltage BMS. Traditional EV battery monitoring typically requires separate shunt and current sensor components to achieve necessary safety levels while measuring currents up to 2000 amperes.

“The HSU represents a significant innovation in sensor technology, being the first to combine shunt and Hall effect sensing into a single component,” said Jérémie Piro, Product Manager Battery Management Systems and Battery Storage at LEM. “This integration simplifies system architecture, enhances safety, and allows for seamless upgrades without altering the mechanical layout. Additionally, it reduces the total bill of materials and minimizes cycle time at the customer’s end.”

The component integrates into battery disconnect units, where it monitors current flow for three critical functions: managing battery state of charge and health, ensuring system safety, and supporting cell balancing optimization. The dual-technology approach allows system developers to meet ASIL D safety requirements mandated for EVs.

Technical specifications include a shunt resistance of 25 microohms and galvanic isolation for the Hall effect section. The Hall sensor provides accuracy of 2 percent at 500 amperes and 5 percent at 2000 amperes. Both sections operate across temperatures from minus 40 to plus 125 degrees Celsius and handle current measurements up to 2000 amperes for 10-second durations.

The HSU fits standard shunt footprints, enabling direct replacement installations without mechanical modifications. LEM initially offers the HSU00 model for 84 x 36 x 3 millimeter busbar configurations, with the HSU01 variant for 84 x 20 x 3 millimeter applications scheduled for release this month.

Signal communication operates through separate pathways, with the shunt providing direct voltage signals while the Hall section communicates via analog or digital interfaces. The unit includes negative temperature compensation for shunt accuracy across operating temperatures.

BMS in EVs monitor individual cell voltages and temperatures while controlling charging and discharge rates. Current sensing components provide data essential for calculating remaining range, preventing overcharging, and detecting potential safety issues.

LEM plans to expand the HSU product line by incorporating additional technologies, including coreless Hall effect sensors combined with shunt elements. The company aims to further reduce component size and cost while improving measurement performance.

Samples of the current HSU models are available for evaluation by automotive manufacturers and battery system suppliers.