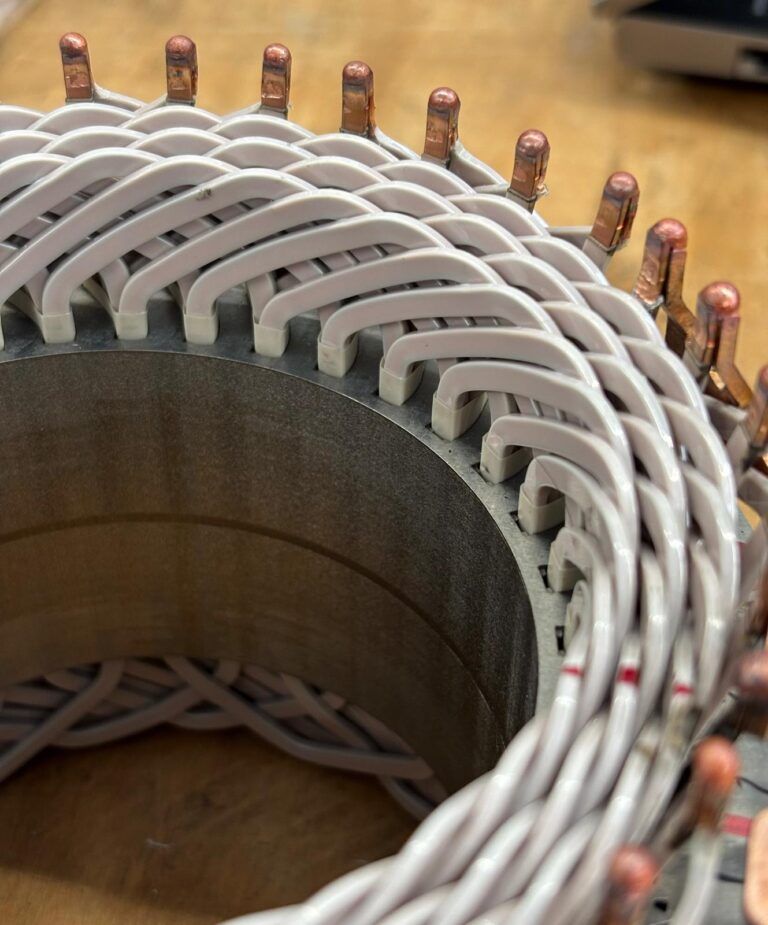

Materials company Syensqo has partnered with Mavel Powertrain to supply advanced polymer components for a high-voltage electric motor destined for a premium sports car manufacturer. The collaboration centers on Syensqo’s Ajedium PEEK slot liners and slot wedges, along with KetaSpire PEEK magnet wire insulation.

The materials enable the motor to operate at voltages exceeding 800 volts while improving thermal management and electrical output. The reduced thickness of the PEEK components allows for increased copper content in the motor design, enhancing overall efficiency.

“We are excited to collaborate with Syensqo and integrate their advanced Ajedium and KetaSpire PEEK solutions into our latest high-voltage electric motor,” said Luca Favre, Head of Motor Development at Mavel Powertrain. “Material excellence is at the core of our commitment to delivering cutting-edge electric powertrains to our automotive customers.”

The polyetheretherketone (PEEK) materials address thermal and electrical challenges in high-performance electric motors. Slot liners and wedges provide insulation between motor windings and the stator core, while the magnet wire insulation protects copper conductors from heat and electrical stress.

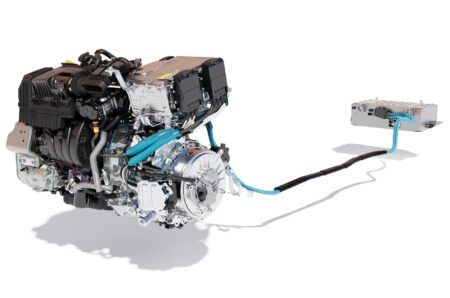

Brian Baleno, Director of Global Business Development and Program Management at Syensqo, emphasized the partnership’s significance for electric vehicle development. “We are proud to partner with Mavel on a project that demonstrates the tangible improvements in efficiency that our solutions bring to electric vehicles,” he said. “This development is an important stride towards increasing the viability and capabilities of battery electric vehicles, plug-in hybrid electric vehicles, and hybrids.”

Syensqo also manufactures Amodel PPA and Ryton PPS materials for motor busbars and connectors, as well as Xencor PPA LFT for additional slot wedge applications. The company has not disclosed which sports car manufacturer will use the motor technology.