A new electric vehicle battery technology has been unveiled that claims to offer charging speeds that are comparable to the time it takes to refill a typical fossil-fuelled car.

Mahle Powertrain and Allotrope Energy have combined the benefits of super capacitors and traditional lithium-ion batteries, to create the new lithium-carbon technology and its ultra-fast charging capability. In addition, Li-C cells are free from rare-earth metals, are fully recyclable, and are not susceptible to the runaway events

“Range anxiety is often quoted as the main barrier to electric vehicle adoption, but if the battery could be recharged in the same time it takes to refuel a conventional IC engine vehicle, much of that worry goes away,” said Dr Mike Bassett, Mahle Powertrain’s Head of Research.

“With the rise of the on-demand economy, there’s been a rapid increase in the use of petrol-powered mopeds for urban deliveries such as take-away meals, and this has contributed to air quality issues in our cities,” continued Bassett. “Decarbonising these deliveries has so far proved difficult without maintaining a stock of expensive interchangeable batteries or switching to a larger, heavier electric vehicle with increased energy consumption.”

However, in a collaborative project with Allotrope Energy, MAHLE Powertrain has considered how an electric moped could be used as an urban delivery vehicle powered by an inexpensive small capacity lithium-carbon battery that could be recharged between stops in as little as 90 seconds.

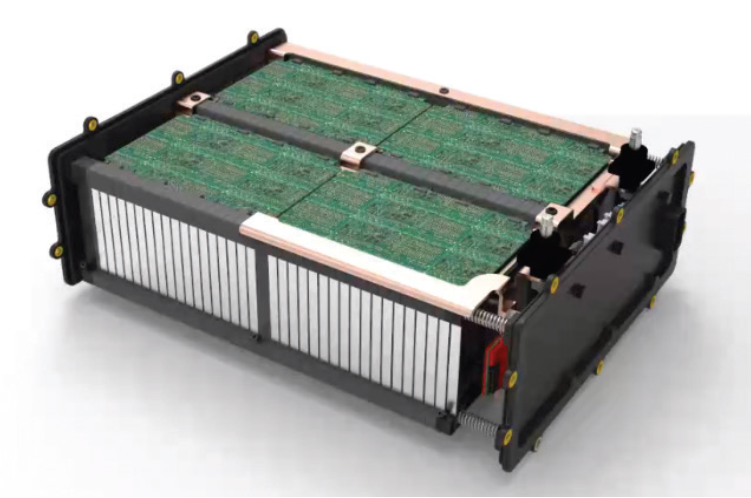

Allotrope Energy’s lithium-carbon technology combines the benefits of super capacitors and traditional lithium-ion batteries to deliver a cell that can be recharged quickly and yet retains good energy density. The technology features a high-rate battery-type anode and a high-capacity electric double layer capacitor (EDLC)-style cathode, separated by an organic electrolyte.

The result is said to make a battery cell with that suffers none of the thermal degradation effects experienced by traditional lithium-based batteries. Its stability, even at high temperatures, permits high current delivery and fast recharging, all without the need for complex external cooling or elaborate battery management systems.

Additionally, its capacitor-style cathode claim a lifetime of over 100,000 cycles, far greater than conventional batteries, while the elimination of rare-earth metals and the design’s complete recyclability make it better for the environment both during production and long after it.

As part of the project, Mahle Powertrain investigated the scenario of a city-based e-moped fast-food delivery service with a 25 km target range. A 500Wh conventional lithium-ion battery would require a recharge mid-shift that, even with a fast-charger, would take more than 30 minutes. In addition, regular fast charging reduces battery life to the point it would likely need replacement every year or two.

A lithium-carbon pack, however, could be recharged at 20 kW in just 90 seconds, meaning a full charge could be achieved in the time taken for the next delivery to be collected.

“With ultra-fast charging, the size of the battery can be optimized to suit the scenarios the vehicle will be used in, and that leads not only to weight savings but also cost reductions that further lower the barriers to decarbonization,” Bassett pointed out.

“The real challenge came in designing the electrical architecture capable of absorbing such high rates of charge,” said Bassett. “Additionally, with no suitable charging systems on the market that can deliver these charge rates from a domestic supply, we created our own bespoke design.”

The solution Bassett’s team came up with uses its own built-in capacitor-based energy store to deliver ultra-fast charging up to 20 kW by augmenting the power from a typical 7 kW single phase connection, thereby reducing cost and complexity while eliminating the need for expensive power grid connection upgrades.