The British Standards Institution (BSI), in its role as the UK National Standards Body, has published the first code of practice for the safe and environmentally-conscious handling of batteries for electric vehicles.

It is the first publication from the Faraday Battery Challenge Standardization Programme, which is delivered with support from UK Research and Innovation as part of the government’s £317 million investment to address the UK productivity gap in the EV market. The standard, and others which will follow it, is intended to help scale-up and advance the production, safe use and recycling of batteries in the UK, in a growing market worth an estimated £5 billion in the UK and £50 billion across Europe by 2025.

As the UK prepares for the future ban on the sale of petrol and diesel vehicles, the new standard will help to reduce health and safety risks and create environmental best practices throughout the life cycle of EV batteries.

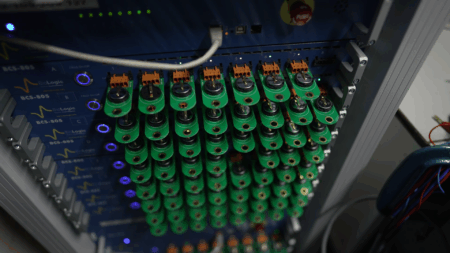

The new standard, PAS 7061 Batteries for vehicle propulsion electrification – Safe and environmentally-conscious handling of battery packs and modules – Code of practice, outlines best practice from sourcing material, through to manufacturing, use and disposal.

It will help companies involved in pack and module battery manufacture to innovate quickly, safely and sustainably as the UK seeks to make its mark on this emerging international industry. It will also help vehicle manufacturers, dealerships and recycling organizations to manage risks when handling batteries throughout their lifetime. The standard covers eleven handling themes including storage, hazards and fumes.

Scott Steedman, Director of Standards at BSI, said: “More efficient, reliable and affordable batteries for storing electricity are vital to the UK’s transition to a zero-emission transport future. Anticipating an era where electric vehicles become the norm, BSI has published the first consensus standard for handling electric vehicle battery packs and modules. The new standard, PAS 7061, was developed under the Faraday Battery Challenge Standardization Programme and will underpin innovation and mass production of new battery technology. The standard is an important step in creating a successful UK battery manufacturing industry and will help the UK prepare for any future phasing out of diesel and petrol vehicles.”

Tony Harper, Director of the Faraday Battery Challenge said: “The Faraday Battery Challenge is the UK’s mission to be self-sufficient in battery manufacturing by 2035. To leap forward as a nation, we are finding those critical barriers and overcoming them as a collaboration between the public sector and industry. This Publicly Available Specification has boldly started the process of codifying the knowledge held in the UK between manufacturers, test houses, trade associations and regulators working with us, BSI and many other partners. This process of collaboration is powerful to those involved, protecting the environment, creating safer practices and better modules and packs that will benefit UK practitioners and companies alike. I am delighted to see it being launched at the Cenex LCV2020 event.”

This standard has been produced by a steering group2 of technical experts made-up of organizations from the battery manufacturing and automotive industries, regulatory bodies, and representatives of the UK research and development community and consumer interest groups.

The Faraday Battery Challenge Standardization Programme also includes further standards which will complement this one. Due to publish in January 2021, they cover safety, environmental and quality considerations in cell manufacturing and in the design and use of batteries.3 Work is also being done to develop a roadmap which identifies additional areas where standards are needed to support the UKRI’s Faraday Battery Challenge ambitions, making this standard the first of many to define aspects of best practice in EV batteries.