JLR has implemented a £100m initiative to reuse, refurbish and repurpose equipment across its European manufacturing facilities as the company transitions to EV production. The program has redeployed over 50,000 square meters of equipment – equivalent to seven football pitches – from Castle Bromwich and other facilities to active production sites.

The company has redirected thousands of tools and machinery pieces from Castle Bromwich, which ended production last year, along with equipment from its Electric Propulsion Manufacturing Centre in Wolverhampton and operations in Graz, Austria. Equipment has been relocated to JLR sites across the UK and Slovakia.

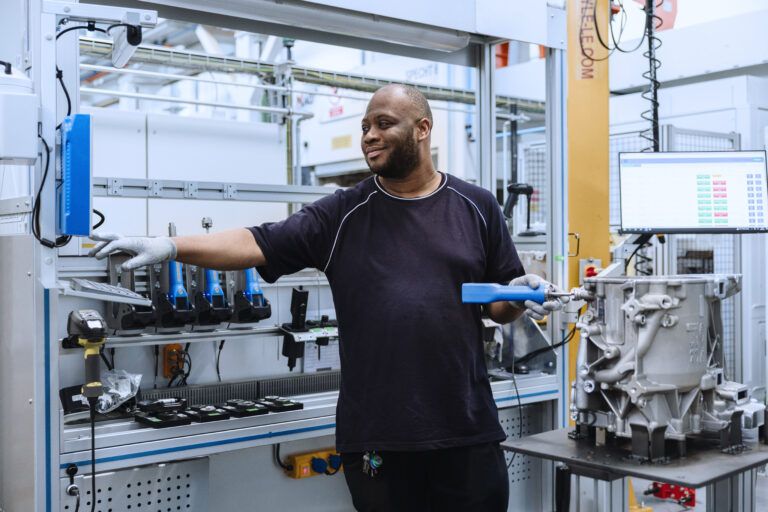

Hundreds of industrial robots have been given a second life and installed at Solihull, Halewood, and Wolverhampton facilities, where they will be used to produce JLR’s next generation of EVs and battery packs. The program supports JLR’s commitment to deliver electric models across all its brands by 2030 and achieve net zero emissions by 2039.

In addition to equipment reuse, JLR has sent 18,600 tonnes of scrapped metal from Castle Bromwich and Graz for recycling, reducing CO2 emissions by approximately 1,258kg per tonne compared to producing new steel.

“As we are entering a critical phase in our electrification journey, JLR has at heart and aims to act as a responsible user of resources by enhancing product utility and longevity, and maximising recycling and repurposing,” said Andrea Debbane, Chief Sustainability Officer at JLR. “It’s not only the right thing to do, but it also improves profitability and increases supply chain resilience. Through these initiatives, JLR advocates that sustainable choices are not always more expensive, they can help reduce costs and even become opportunities for the growth and development of our colleagues.”

The initiative has been managed by a cross-functional team working across sites and technologies to identify reuse opportunities. JLR has also developed a new in-house digital management system to track assets throughout their lifecycle and create an internal marketplace for equipment reuse.

The project has provided JLR staff with new technical skills in refurbishment and recalibration of manufacturing equipment, bringing tools back to production standards on site rather than purchasing new replacements.