As the automotive industry pivots towards stringent new environmental standards, one company has developed the ‘world’s most sustainable audio’ solution to accelerate vehicles towards carbon neutrality.

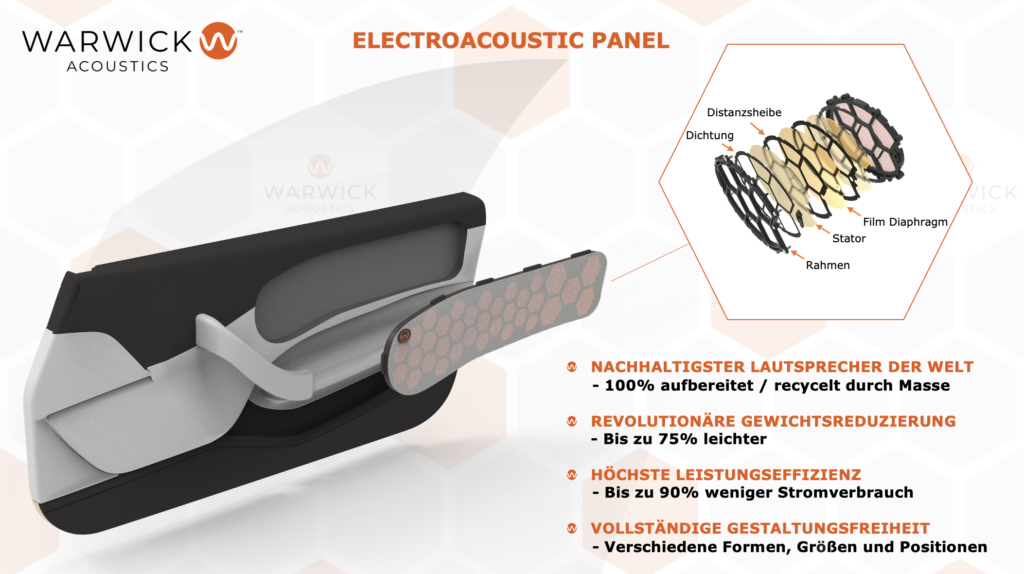

Leading the ‘clean sound revolution’, Warwick Acoustics has created the future of in-car audio systems. ‘Clean Sound’ ElectroAcoustic Panels directly enable automotive OEMs to accelerate their journey towards carbon neutrality.

ElectroAcoustic Panels are produced exclusively from 100% by mass upcycled and recyclable materials, with no rare-earth metals and via environmentally friendly manufacturing processes, providing OEMs with superior leverage to decarbonize their supply chains in the pursuit of end-to-end carbon-neutrality and positivity.

When compared to existing conventional in-car audio systems, ElectroAcoustic Panels are on average up to 75% lighter, and consume up to 90% less power. Hence, not only are they inherently green, but they also deliver additional CO2 benefits to OEMs and customers by contributing to enhanced EV range and lower vehicle battery requirements.

Research published by EDAG – the world’s largest independent engineering service provider in the automotive industry – states that automotive OEMs’ adoption of ‘clean’ audio technology has the realistic potential to achieve major reductions in CO2 emissions from EVs.

According to EDAG, users utilize their car audio system for roughly 260 hours per year. Given this level of use, a 1W reduction in audio system power consumption of an EV vehicle would save approximately 80g of CO2 emissions per year through reductions in electricity generation. With an ElectroAcoustic Panel audio system saving on average 50W of power consumption (up to 10x this amount in high specification systems), EAPs can save on average just under 4kg of CO2 emissions per vehicle per year in primary power consumption savings. When applied across the EU’s 246m cars, this would represent emissions savings in the order of 1 megatonne of CO2 per annum.

Mike Grant, CEO of Warwick Acoustics, comments: “As automotive manufacturers undertake the rapid transition to electric mobility and a circular economy, every element of their supply chain and manufacturing process falls under close scrutiny. As the noise of the internal combustion engine is lost in the transition to EV, shaping the acoustic environment within a vehicle is a fundamental opportunity for manufacturers to redefine their competitive positioning in the market, and where only sustainable innovation will enable them to succeed.

“Warwick Acoustics’ commitment to making a positive contribution to the automotive industry meeting its environmental goals, including the decarbonization of supply bases and the onboarding of new, sustainability-focused partners, is reflected in the technological solutions we provide. Our ElectroAcoustic Panels provide the ideal green solution to automotive OEMs seeking to implement a highly sustainable, recyclable, power and weight efficient and brand-defining solution into their products.”

ElectroAcoustic Panels are exclusively comprised of 100% by mass upcycled and recyclable materials, including advanced polymer constructions from leading global materials partners and waste materials used by other industries such as the IT industry. Unlike conventional systems, ElectroAcoustic Panels contain no rare earth metals, avoiding the need for environmentally damaging mining techniques.

Headquartered at new state-of-the-art facilities at MIRA Technology Park, Warwickshire, at the very heart of the UK’s automotive industry, Warwick Acoustics factory will soon benefit and be powered by renewable energy resources on-site through clean, green hydrogen technologies and Solar Farms. Warwick Acoustics is also on track to achieving ISO 14001 certification in the near future to support the goal of reaching full carbon neutrality.

Supreme Power Efficiency

According to EDAG: “The [average] operation of an electric car calls for 2,157 kWh a year (charging loss not included) – leading to emissions of 683 kg CO2 a year. In 2020, a total of 1.4 million electric vehicles were sold in Europe. If the electric and electronic design of these vehicles were to be altered in such a way that the continuous power was reduced by just 1 watt (-0.01235 %), this would result in a total saving of 118,090 tonnes of CO2 per year of operation. To elucidate: this is equivalent to the total annual emissions produced by 173 electric vehicles.”

ElectroAcoustic Panels’ electrostatic technology consumes significantly less power to deliver the same audio output as a traditional system. The close analogy here is an LED light bulb versus an incandescent filament light bulb.

Given the ultra-low mass of the ElectroAcoustic Panel’s Transducer and capacitive nature of the load, power consumption of the electronic drive module is exceptionally low, with typical average power requirements as low as 10% of that required to drive a conventional transducer. In the case of application to an electric vehicle, demands on power supply are greatly reduced, aiding in overall vehicle range.

Revolutionary Weight Savings

ElectroAcoustic Panels are lightweight, ultra-thin, and up to 75% lower in mass than existing audio technology. ElectroAcoustic Panels are therefore particularly beneficial to EVs where weight is at a premium with heavy, low energy density battery packs and where every kilo reduction in weight improves driving range and performance.

In typical automotive audio systems, conventional speakers are dependent on much heavier and unsustainable magnet-activated diaphragms to generate sound.