Eaton has been selected by a major global automaker to supply its High-Power Lock Box SQ8 connector system for a new plug-in hybrid EV platform, marking the first deployment of the SQ8 configuration in a hybrid application.

John Romain, product management director for Eaton’s Mobility Group, said the system represents a significant advancement in terminal technology. “The HPLB SQ8 connection system is a leap forward in terminal technology,” Romain said. “We’ve designed a power-dense, compact and ergonomic solution that delivers performance comparable to bolted connections – without the need for specialized tools or high insertion forces. It’s a game-changer for electrified vehicle platforms.”

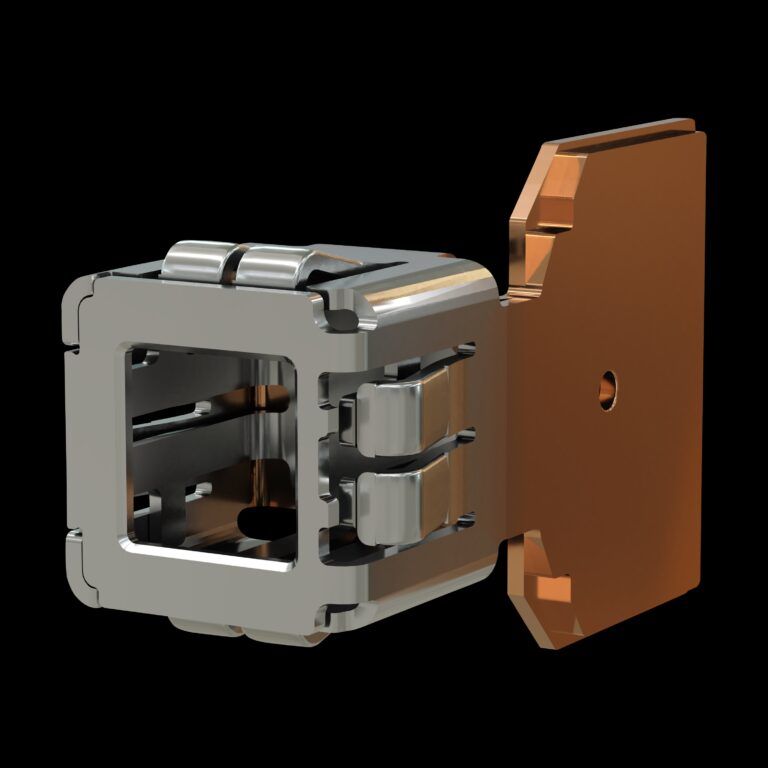

The SQ8 variant builds on Eaton’s connector technology designed for harsh environments and high-current applications. The system features a patented, inverted terminal contact design engineered for electrical performance and durability under high temperatures, vibration and mechanical stress.

Unlike traditional terminals that rely on copper for both conductivity and spring tension, Eaton’s design uses a stainless-steel spring to maintain contact force and a copper current carrier for conductivity. This architecture is intended to prevent mechanical relaxation and failure common in high-vibration EV environments.

Testing and benchmarking against competitor data showed the HPLB SQ8 terminal delivers 25 to 35 percent improvement in current-carrying capability for a given wire size. The system also provides 30 to 60 percent more current per unit of volume, which can reduce vehicle platform weight and improve power distribution efficiency.

The connector system can carry up to 270 amps of current with minimal resistance loss, making it suitable for battery disconnect units, high-voltage heaters and propulsion systems in electric, hybrid and commercial vehicles. The system uses a tool-free push-click-pull mating process that provides secure connections with just 70 newtons of force, eliminating the need for mechanical levers.

Key specifications include compatibility with 25 to 70 square millimeter wire gauges, flexible 90-degree and 180-degree terminal orientations, and eight spring-loaded contact points. The system operates at temperatures up to 125 degrees Celsius and includes QR-code-enabled part traceability.

The HPLB connector family was initially introduced in commercial truck platforms and electric vehicle applications. The four-contact SQ4 variant has seen field use, while the SQ8 is now available for heavy-duty pickup trucks, battery disconnect units and other electric vehicle applications.

Romain noted the system’s scalability for future applications. “HPLB is future-ready,” he said. “It meets today’s high-voltage, high-durability demands – and it’s already positioned to scale across the next generation of electrified platforms.”