Off-highway electrification presents unique challenges compared to automotive applications, with battery requirements reaching 500kWh and duty cycles varying dramatically. Industry leaders highlight the need for integrated solutions, smart charging systems, and early collaboration between vehicle and battery manufacturers.

Vehicles are being electrified around the world, but unlike the automotive sector’s relatively straightforward transition to electric power, off-highway applications present unique challenges that demand innovative solutions and rethinks of traditional approaches.

On power requirements alone the differences are stark – whereas automotive applications might require 50-100kWh of battery capacity, off-highway vehicles can demand 400-500kWh or more.

And within off highway, each application demands different solutions, different compromises, and different innovations – from construction sites where 40-ton excavators operate around the clock, to warehouses where autonomous mobile robots and forklifts must navigate narrow aisles.

Duty cycles compound the complexity of electrification. “You’ve got machines that maybe work two to four hours during the day with the rest being idle hours, versus a haul truck that may run literally 24 hours a day with three or four operators,” says Dr Ray Gallant, vice president of Sustainability and Productivity Services at Volvo Construction Equipment.

This variation creates what Gallant describes as a grid of applications, plotted against hours of use per day and power requirements. “The larger the machine, the more the power requirement. And smaller, compact machines generally see shorter duty cycles during the day.”

For manufacturers, this means there’s no one-size-fits-all solution. Battery-only works well for smaller equipment with shorter duty cycles, but as power requirements increase beyond 300kWh and duty cycles extend to full shifts, other technologies come into play – hybrid drives, alternate fuels, grid-connected machines, and even hydrogen fuel cells for the heaviest applications.

Fully integrated battery solutions

Perhaps nowhere is the transformation more evident than in the material-handling sector, where Crown Equipment has reimagined the relationship between vehicle, battery, and charger by delivering a fully integrated solution called V-Power, which eliminates the need to rely on third-party technology.

Trevor Bonifas, general manager for motive power at Crown explains the reason for the new offering: “A lot of our customers have basically come to us and said, ‘We’re tired of the finger pointing’. The battery caused the truck to have a problem. The truck caused the battery to have a problem, or the charger now impacted all of it.”

While lift-trucks have been running on lead-acid batteries for decades, the issue of battery compatibility was heightened by the advent of lithium batteries. “Lead acid batteries are dumb,” says Bonifas. “You can trick them to work in anything, but with lithium batteries, there’s a brain on them. There’s a central control unit. And if the battery stops giving power to the truck, it’ll lock the brakes up.”

In response to the growing compatibility problems Crown Equipment established its motive power division in 2020, offering integrated solutions where truck, battery, and charger are fully integrated at the design stage. “We wanted to give a unique experience to our customers, where it was one service provider, so they could get the truck, the battery and the charger from one company,” says Bonifas.

Other lift-truck vehicle manufacturers are beginning to share the Crown ethos of fully integrating battery systems. John Barilleaux from Hubtex, which manufactures side loaders, describes the challenge: “In a lot of cases, companies will design AGVs (automated guided vehicles),” he says. “Customers will spec an AGV that they want. They’ll work with a company to develop a product, and then they get all the way through the design cycle, and they realize they need a battery.

“The battery is the heart and soul of the AGV,” says Barilleaux. “Nothing works without a battery, and the battery has to communicate with the AGV or AMR (autonomous mobile robot), in order for the machine to operate and do the job that it needs to do.”

Robin Schneider from Green Cubes Technology, a lithium battery manufacturer, emphasizes the importance of early collaboration: “Having cohesive communication between the AMR and AGV manufacturer and their development team and the battery manufacturer and their development team is really key to making sure that you have a successful implementation.”

Real-world performance

The theoretical benefits of electrification are now being validated by real-world data. Volvo’s trials in Southern California provide compelling evidence of the transformation’s potential. Running a EC230 Electric excavator for 122 hours, the company achieved dramatic results: “Carbon emissions into the atmosphere were down by anywhere between 65 and 80%,” says Gallant. This in turn translated into fuel savings of 82% comparing the cost of electricity with the cost of diesel.

But Gallant is careful to set realistic expectations about the broader implications: “Electric machines have about 35% less repair and maintenance, but what about battery replacement? That is a very real consideration. The batteries do degrade. They do wear out.” Even accounting for complete battery replacement during the machine’s lifecycle, “your repair and maintenance savings then drop to about 6%.”

That said, Volvo’s estimates on battery life may be too conservative. Crown’s experience with AGV systems, running 48-volt, 200 amp-hour batteries in constant use since 2018, have exceeded expectations. “These were brought in in 2018. I took some measurements on these batteries a few weeks ago and the cells are still above 80% of what their original capacities were,” says Bonifas. “They’re an older cell technology, and they really were only rated to do about 1,000 cycles. And I’m sure we’re well over that, probably in the 3,500-cycle range.”

Green Cubes’ data is also promising, showing that “lithium-ion batteries can increase productivity and lower the total cost of operation by about 30%. They are also about 98% efficient versus 80% efficient with a lead acid battery.”

Charging ahead

Crown’s V-Power system extends beyond vehicle technology to include charging systems and sophisticated power management to address one of electrification’s biggest challenges – grid demand. “We’re charging at such high rates and probably a little more frequently than we would have with lead acid, especially in those high-demand applications,” says Bonifas. “So, we have developed products that can basically shave the demand at certain times of the day, so we can basically control and lower electrical utility bill from a specific customer based on charging at certain times of the day.”

The system is predictive rather than reactive. “Each solution is a little bit different for every single customer,” he says. “Instead of pulling 40kW, we’re going to limit them to 20kW, because they only need X number of trucks running during that third shift or second shift.”

This intelligence extends to individual vehicle behaviour. For AGVs, the constant power draw creates unique challenges. “Where a regular forklift maybe will drop down to less than an amp of current when idle, an AGV has got all the sensors always running,” says Bonifas. “The IPC (instrument panel cluster) is always running. It’s always communicating with the server. So, in some cases, we’re drawing five to six amps of current just sitting idle.”

Volvo’s Gallant agrees with the need for smart energy management as the key to developing sustainable sites. “We can do a lot of things to improve the site, to improve the workflow, but if we focus on energy management, we can get it to a sustainable point,” he says.

Green Cubes is also working on optimising charging and has developed multi-voltage systems that can reduce charging time by 50%. “You charge at double the voltage and half the current, and then you discharge at double the current and half the voltage, so it’s constant power,” says Schneider.

Looking Forward

The industry’s trajectory suggests that current solutions represent just the beginning of a longer transformation. Bonifas at Crown anticipates fundamental design changes: “As lithium batteries get more integrated into the truck, it’s going to be a smaller area where the battery is, which could lead to a complete redesign of how forklifts look. But it’s going to take a while for the parts, the aftermarket, and everything, to catch up to the new ways of doing things.”

The industry’s transformation represents what Gallant calls a journey rather than a destination. “We view sustainability as basically a balance between three pillars – social, environmental, and economic sustainability,” he says. “We must keep these three pillars in balance.

“Faith in the future gives us power in the present,” says Gallant. “We have the people that can solve this. We know how to do it. The technology is maturing. If we have faith that we will get there, we will have the courage and the ability to take the steps that we need to do in the present to make it happen.”

Supplier Spotlight: Aliant Battery

Aliant Battery, a division of Elsa Solutions, specializes in the design, production and development of lithium batteries for industrial vehicles and heavy-duty applications. Aliant Battery storage solutions are tailored to customer needs, ensuring maximum interoperability between battery and machine and optimization of performance.

The ability to produce fully customized batteries in a short time and maintaining high standards is the result of the know-how gained in the most complex and demanding industrial fields in terms of certifications and reliability of components, in addition to a vision oriented towards constant improvement and technological innovation.

The company can boast over 40 years of experience in the world of industrial power electronics, and it continues to grow and develop with the recent expansion of manufacturing capacity and the adoption of a cutting-edge robotic lithium battery production line, with the target for an annual production of over 200 MWh.

Aliant Battery sees R&D as a fundamental pillar for the future: the introduction of new specialized figures and latest-generation design and simulation software, and the simultaneous development of advanced solutions demonstrate the company’s commitment to maintaining a technological advantage, such as the development of a solid-state battery.

Supplier Spotlight: Flash Battery

Since 2012, Flash Battery has been designing and manufacturing customised lithium batteries for off-highway vehicle OEMs with medium production volumes and high tailoring requirements. Its strong focus on the industrial market has led to the development of custom-made battery solutions that meet specific space constraints and deliver the required voltages and power for each application.

A key technology is the patented BMS, the Flash Balancing System, which provides high-power (20A) active and passive balancing during both charging and discharging. It actively supports weaker cells, ensures full temperature control with two sensors per cell, enables zero maintenance, and guarantees short and predictable charging times, with a balancing time under 30 minutes.

Flash Battery’s lithium batteries are also connected to the Flash Data Center: a cloud-based remote-control system that uses AI and machine learning to analyse data from all active battery systems worldwide. The core feature is automatic data control: performance is monitored daily to detect and eliminate false reports and anomalies through predictive maintenance and over-the-air updates. Thanks to it, every battery can be monitored 24/7, malfunctions are instantly reported, and extraordinary maintenance is efficiently scheduled. This eliminates maintenance costs, increases productivity, prevents anomalies, and predicts the battery’s future behaviour and end-of-life, making Flash Battery a leader in intelligent lithium battery systems.

Supplier Spotlight: Proventia

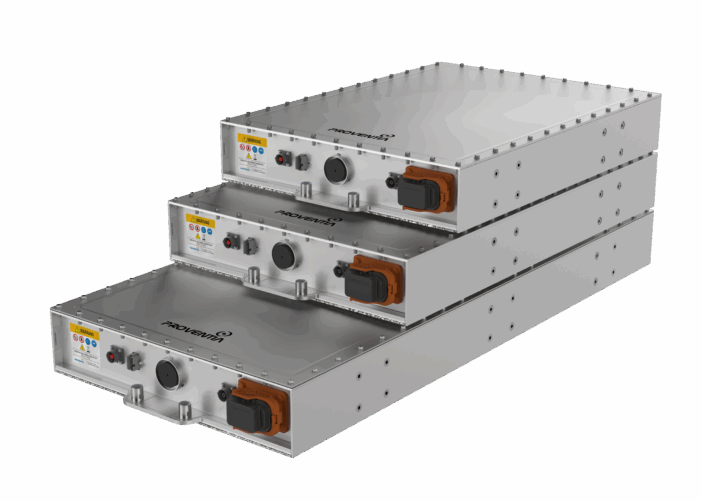

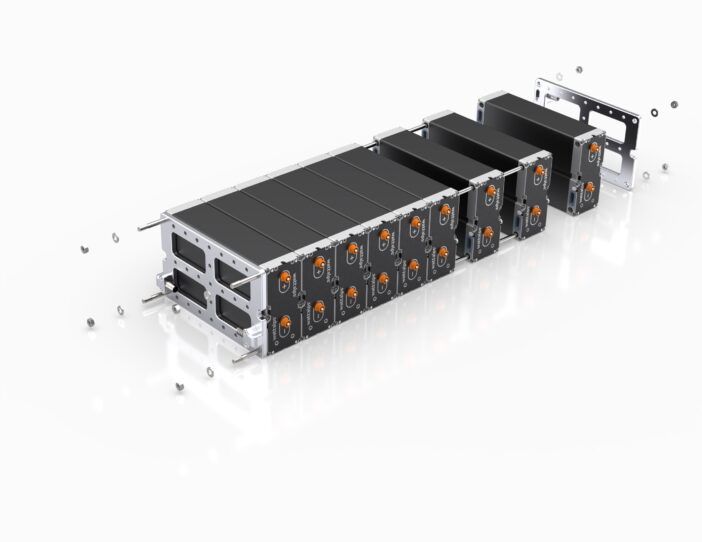

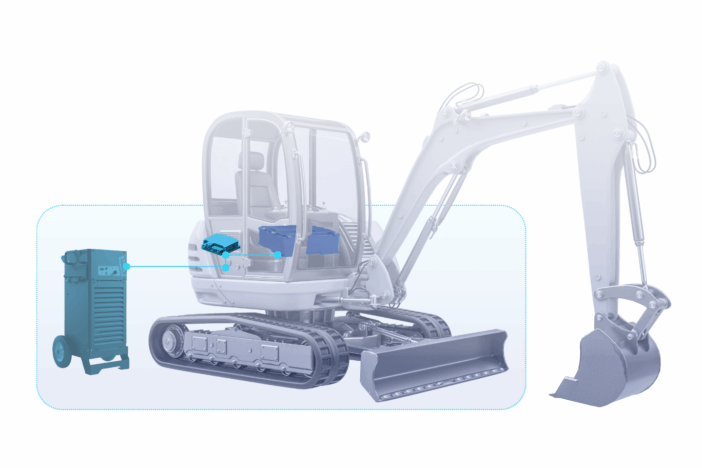

Proventia is a Finnish technology company committed to reducing emissions and improving energy efficiency in the non-road mobile machinery (NRMM) sector. It is strengthening its role in clean power innovation through its modular lithium-ion battery packs and electric powertrains for hybrid, fully electric, and fuel cell applications.

Proventia’s Energy Batteries, based on lithium iron phosphate (LFP) chemistry, offer high performance, long cycle life, and excellent thermal stability. These characteristics make them particularly suitable for heavy-duty full electric applications such as wheel loaders, excavators, and material handling equipment.

The batteries use cells from Norwegian Morrow Batteries, ensuring European quality and traceability. In addition, LFP chemistry brings key sustainability benefits. Free from cobalt and nickel, and featuring a lower carbon footprint, LFP technology supports OEM decarbonization goals.

Proventia’s Power Batteries utilize lithium titanate oxide (LTO) chemistry, providing exceptional safety, an even longer cycle life, stability in extreme conditions, and high C-rates, ideal for demanding non-road machinery peak shaving.

For seamless machine integration, Proventia’s Technology Centre supports simulation and control system development during design phase. Combined with the Test Centre for battery and hybrid system testing, Proventia offers a complete development environment for next-generation electric powertrains.

Supplier Spotlight: Wattalps

Wattalps designs and manufactures high-performance lithium-ion batteries, using a patented immersion cooling technology. This technology enables to push further the limits of classical li-ion batteries, by increasing their performance, their life and their safety.

In addition to outstanding thermal management efficiency, Wattalps immersion cooling technology provides a high level of passive safety against thermal runaway propagation.

Thanks to Wattalps’ BMS, with hardware and software designed in-house, Wattalps guarantees excellent functional safety certified according to ISO 26262 up to ASIL C. The dielectric fluid used for Wattalps’ batteries is biodegradable, non-toxic and non-flammable.

The modular design of the packs allows for a fast integration phase and very compact solutions with high energy density and extreme power output.

Wattalps’ solutions are available in three families, adapted to the specific applications of our customers, favoring either the extreme compactness of the High Energy packs, or the possibility of repeated fast charging for the Fast Charge and Life packs, or the ability to withstand very high current peaks for the Performance Power packs, which are particularly well suited to machines hybridization.

Supplier Spotlight: Zapi Group

As electrification transforms the off-highway sector, construction equipment OEMs require charging solutions specifically engineered for non-road mobile machinery (NRMM) applications. Mid-power charging requirements of 2-20kW machines require compact, rugged and reliable solutions exposed to demanding operational environments. Advanced 3.3kW solutions now deliver IP66/IP67-rated protection against dust and water while withstanding mechanical shock, impact, and vibration fatigue. Worksites typically employ both on-board chargers (featuring intuitive machine-user interfaces and full communication with vehicle master controllers) and portable off-board chargers that provide charging accessibility across remote worksites lacking charging infrastructure.

Zapi Group’s charging solutions, delivered through member companies Delta-Q Technologies and Zivan, cater highly integratable solutions to this dual approach while maintaining compatibility with diverse battery chemistries and communication protocols. Developed through strategic OEM partnerships, rigorous testing and conformance to internationally recognized certifications, Zapi Group’s Charging Solutions help operators achieve maximum performance and low cost of ownership from electrification investments across international markets.

For off-highway professionals navigating the transition from combustion to electric powertrains, selecting providers with deep expertise and comprehensive technology portfolios proves essential for successful electrification strategies in this rapidly evolving sector.

The manufacturing reality

As OEMs shift to building batteries in-house, so they must get to grips with the challenges of a new type of quality control. In battery manufacturing CT scanning technology can be used to detect foreign particles from welding processes, anode and cathode positioning issues, and structural defects that cause thermal runaway.

Roger Wende is senior business development manager for Hexagon Manufacturing Intelligence, which has been working on CT scanning technology for battery inspection. He highlights the quality control challenges: “Battery manufacturers know what they’re looking for in a CT scan, but they’re just doing it by eye – it’s a manual process. They’ll maybe get some of the basic instruments to do measurements.”

Hexagon is introducing AI and machine learning to reduce inspection time from hours to seconds, using deep segmentation technology. “If you’re trying to mass produce batteries, it doesn’t make sense to do manual inspections,” says Wende.

Hexagon’s system works by identifying CT artifacts – noise in scans caused by different materials creating visual interference. “It allows me to do some ‘painting’ to differentiate the different materials,” says Wende. “And then create that macro and automate that on every battery scan.”