Daimler Truck will produce 100 Mercedes-Benz NextGenH2 fuel cell trucks starting late 2026, featuring liquid hydrogen storage enabling 1,000-kilometer range. The semi-trailer tractor uses cellcentric’s 300-kilowatt fuel cell system and eActros 600 components, targeting series production in the early 2030s.

Daimler Truck has announced plans to produce 100 units of its Mercedes-Benz NextGenH2 Truck in a small-series production run beginning at the end of 2026. The fuel cell-powered semi-trailer tractor will be manufactured at the Mercedes-Benz plant in Wörth, Germany and deployed with various customers as the company advances its hydrogen-based transportation strategy.

The NextGenH2 Truck builds on the first-generation Mercedes-Benz GenH2 Truck, retaining liquid hydrogen technology that enables ranges exceeding 1,000 kilometers on a single tank at full load. The vehicle incorporates proven components from the battery-electric eActros 600, including the integrated e-axle, the aerodynamically optimized ProCabin, the Multimedia Cockpit Interactive 2, and current safety and assistance systems.

“In addition to battery-electric solutions, hydrogen-based drives are crucial for the sustainable transformation of our industry,” said Achim Puchert, CEO of Mercedes-Benz Trucks. “With the NextGenH2 Truck, we are taking the next technological step in fuel cell trucks. Together with our customers, we aim to introduce the small series with high range and near production-ready technology into daily transport operations from the end of 2026.”

The truck utilizes liquid hydrogen stored at minus 253 degrees Celsius, which provides significantly higher energy density than gaseous hydrogen. Two liquid hydrogen tanks with a combined capacity of up to 85 kilograms can be refueled from either side in 10 to 15 minutes using the sLH2 refueling standard developed by Daimler Truck and Linde.

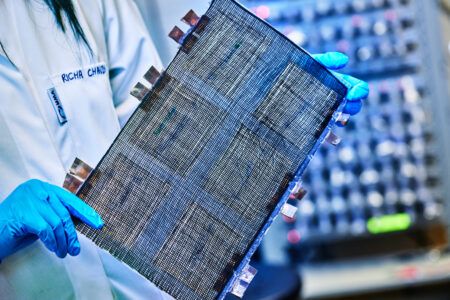

Power generation comes from the cellcentric BZA150 fuel cell system, a joint venture product between Daimler Truck and Volvo Group. Two fuel cell units operate as a twin system with total output of 300 kilowatts, converting hydrogen and oxygen into electrical energy with water vapor as the only emission. Early customer trials with the first-generation GenH2 Truck recorded hydrogen consumption averaging between 5.6 and 8 kilograms per 100 kilometers at gross combined vehicle weights ranging from 16 to 34 tonnes.

The NextGenH2 Truck includes a 101 kilowatt-hour lithium-iron-phosphate buffer battery and the same four-speed electric drive axle used in the eActros 600, enabling energy recuperation during downhill driving and braking. The German Federal Ministry of Transport and the states of Rhineland-Palatinate and Baden-Württemberg are supporting the development and deployment with 226 million euros in funding. Series production is targeted for the early 2030s.