Chalmers University of Technology presented its structural battery technology at Davos that integrates energy storage into vehicle body components. The carbon fiber-based system could reduce EV weight by 25 percent while eliminating separate battery packs, improving range and design flexibility.

Researchers from Chalmers University of Technology in Sweden presented their structural battery technology at the World Economic Forum in Davos, showcasing an innovation that could fundamentally change how EVs are designed and manufactured. The technology integrates energy storage directly into a vehicle’s structural components, essentially making the body of the car function as its own battery.

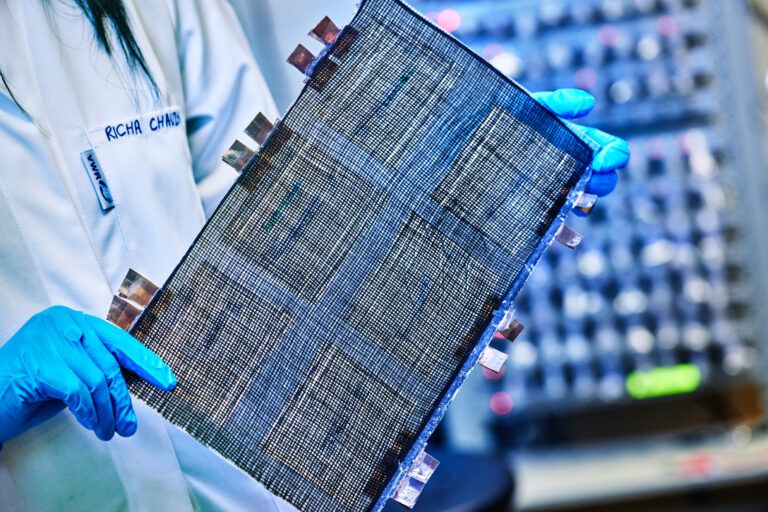

Structural batteries combine load-bearing capabilities with energy storage by embedding battery cells within composite materials such as carbon fiber. Unlike conventional batteries that add weight and occupy dedicated space within a vehicle, structural batteries serve dual purposes as both energy storage and structural support, reducing overall mass while maintaining or improving mechanical strength.

The technology developed at Chalmers uses carbon fiber as both an electrode and a structural reinforcement material. The carbon fiber acts as the negative electrode while a lithium iron phosphate coating on aluminum foil serves as the positive electrode, with a fiberglass fabric separator between them. This configuration allows the material to store electrical energy while simultaneously bearing mechanical loads.

For EVs, the implications are significant. By eliminating the need for separate battery packs housed in dedicated enclosures, structural batteries could reduce vehicle weight by up to 25 percent according to Chalmers researchers. This weight reduction directly translates to extended driving range, as less energy is required to move a lighter vehicle. The technology also frees up interior space currently occupied by conventional battery packs, potentially allowing for more flexible vehicle designs or increased passenger and cargo capacity.

The current prototype delivers an energy density of 24 watt-hours per kilogram, which is lower than conventional lithium-ion batteries that typically achieve 250 to 300 watt-hours per kilogram. However, researchers emphasize that the structural benefits offset this lower energy density. When accounting for the elimination of separate structural components and battery housings, the overall system-level benefits become more favorable.

Chalmers researchers indicated that commercial applications could emerge within several years, though significant development work remains to improve energy density and manufacturing scalability. The presentation at Davos aimed to attract investment and partnerships to advance the technology toward mass production.