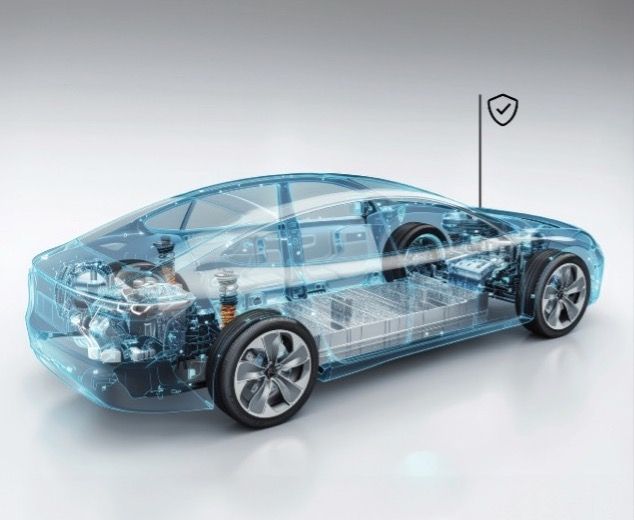

NXP Semiconductors has announced the MC33777, a new battery junction box integrated circuit (IC) for EVs. This device integrates critical pack-level functions into a single component, aiming to simplify battery management systems (BMS) for high-voltage applications.

The MC33777 consolidates essential BMS functions that typically require multiple discrete components, external actuators, and processing support. This integration is designed to reduce design complexity, qualification efforts, and software development costs for OEMs.

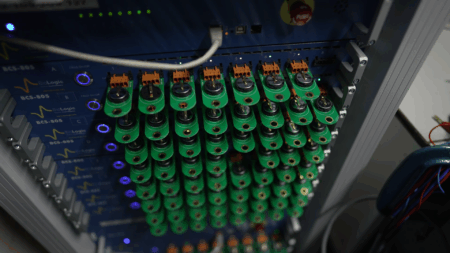

A key feature of the MC33777 is its ability to monitor battery current and slope every eight microseconds, potentially improving protection against overcurrent in high-voltage batteries. The device can detect and respond to various configurable events more quickly than conventional ICs.

“Integrating everything that’s required to monitor a battery pack and react quickly to safety-critical events into a single device delivers significant benefits for both OEMs and the end consumer,” says Jesus Ruiz Sevillano, Director of Product Marketing BMS at NXP. “NXP’s MC33777 marks a new generation of battery junction box ICs for EVs, delivering faster, safer and more affordable management solutions for high-voltage battery packs.”

The MC33777 incorporates fuse-emulation technology, which may allow for the removal of physical melting fuses from the system. This could potentially lead to cost savings and increased reliability. For manufacturers, the MC33777 is said to reduce component count by up to 80%, which could limit required printed circuit board space and reduce software development efforts. This may help accelerate design cycles and shorten time-to-market for new electric vehicles.

The device is part of NXP’s Electrification system solution portfolio, which includes battery cell controllers, battery gateway ICs, and related software and safety documentation. NXP plans to showcase the MC33777 device family at Electronica 2024.