Anaphite claims breakthrough could cut 7 million tonnes of CO2 from battery production

Bristol-based battery technology startup Anaphite has unveiled independent analysis showing its dry coating technology could dramatically reduce carbon emissions from global battery manufacturing. The company announced on November 6, 2025, that its innovative approach to electrode production could save 7 million tonnes of CO2 annually and help original equipment manufacturers meet increasingly stringent EU Battery Passport regulations.

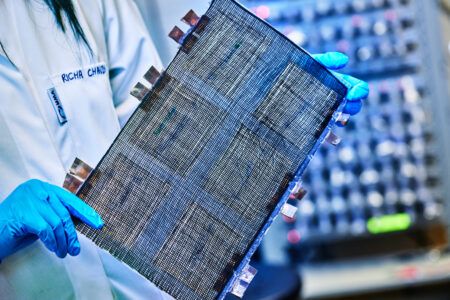

The independent lifecycle sustainability assessment examined Anaphite’s dry coating technology platform for manufacturing battery electrodes. According to the analysis, the dry coating process “can significantly reduce carbon emissions by 3.57 kg CO2 eq. per kWh of cell capacity” when compared to traditional wet coating methods used for over 90 percent of global lithium-ion electrode production.

The technology eliminates the need for energy-intensive ovens required in conventional wet coating processes, which currently dominate battery electrode manufacturing on a vast scale. Anaphite’s patented platform combines essential dry coating ingredients into a single engineered material, specifically designed for high-speed production lines. When paired with the company’s dry coating process, this approach solves a critical challenge that has prevented widespread adoption of more sustainable manufacturing methods.

“Wet coating of electrodes is well proven, but manufacturers want to achieve dry coating because of the carbon footprint improvements scale offers,” said Anaphite CEO Joe Stevenson. He emphasized that the technology addresses both environmental concerns and the practical manufacturing challenges that have historically limited dry coating adoption.

The announcement comes as battery manufacturers face mounting pressure to reduce their environmental impact. The UK Government’s Department for Business and Trade recently funded an Advanced Propulsion Centre UK project involving Anaphite’s technology, which found potential carbon savings “equivalent to around 7 million tonnes if applied to annual global battery production.” With global battery demand expected to double by 2030 and electric vehicles projected to reach 670 million by 2025, accounting for roughly 1.9 TWh in battery production, the company argues that adopting dry coating technology has become essential for sustainable electrification.

Battery Passport requirements from the EU, set to take effect in 2027, will mandate that manufacturers quantify the total carbon footprint of each battery through ISO-compliant Life Cycle Assessment. These regulations could create market access restrictions and fines for non-compliant producers, potentially accelerating industry adoption of lower-emission manufacturing technologies like Anaphite’s dry coating platform.