Comau has developed and deployed an automated e-drive assembly line for Geely Automobile Holdings at its Geely Veremt plant in Ningbo (China), to double the automation of the end-to-end assembly of the electric motor, gearbox and inverter.

Designed in close collaboration with the Geely team, the complete line uses a flexible automatic production system to assemble the permanent magnet motor rotors, gearboxes and electronics drives, in addition to automated quality control and testing. The innovative solution increases the plant’s automation rate from 40% to 80% while delivering a full-scale production capacity of 120,000 jobs per year.

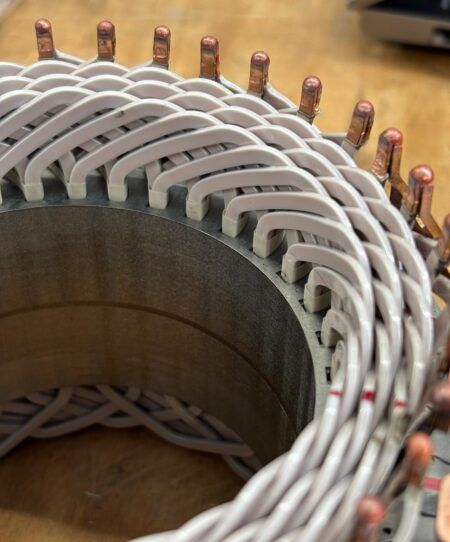

Due to the complexity of the project, the joint technical team worked in close synergy during the entire process. Comau also leveraged its 45+ years of experience in powertrain assembly when combining best-practice technology and process innovations to achieve Geely’s high-volume production targets. Using multiple robots to install the motor rotors, the automated line also features 3D vision positioning and guidance, automatic high-speed magnet installation, automatic injection of rotor cores and the automatic dual-position dynamic balance correction, magnetization and more. The electric drive line, on the other hand, includes advanced three-in-one assembly such as motor stator casing, thermal sleeve, motor static testing, motor dynamic testing, automatic bearing feeding and pressing, automatic bolt feeding and tightening, and the automatic measurement and selection of gaskets.

Since its initiation, Comau has dedicated design resources to the project, including 20 engineers who completed the design phase in just four months. The project execution team also overcame additional challenges due to the impact of the COVID-19 pandemic and product optimization changes, delivering the line in just over 12 months. Thanks to the quick and targeted response to post-delivery modification requests, mass production was officially launched in late 2021.

“We have developed solutions that make our manufacturing process more agile and efficient as a concrete result of our collaboration with Comau,” said Geely Veremt vice president, Sun Yongjing. “Furthermore, the automated lines help ensure that our new products will continue to have the same high level of quality.”