An ultra-high speed ball bearing for electric vehicle motors has been developed that claims to be the world’s fastest grease-lubricated deep groove ball bearing for EV applications.

Capable of operating at over 1.8 million dmN, the technology is said to enable longer vehicle range and higher energy economy for electric vehicles.

Automakers are pursuing smaller and lighter automotive components to help extend the range achievable on a single charge. EV OEMs are also developing faster, higher output motors operating with better efficiencies.

Accordingly, bearings used in powertrains, especially in electric motors, must meet the demand for increasingly higher speeds and performance.

The previous (second) generation of ultra-high-speed ball bearings for EV motors offered 1.4 million dmN and significant advances in cage and anti-seizure technology. However, with the third-generation product, NSK has aligned its solution with the need for bearings capable of even higher speeds.

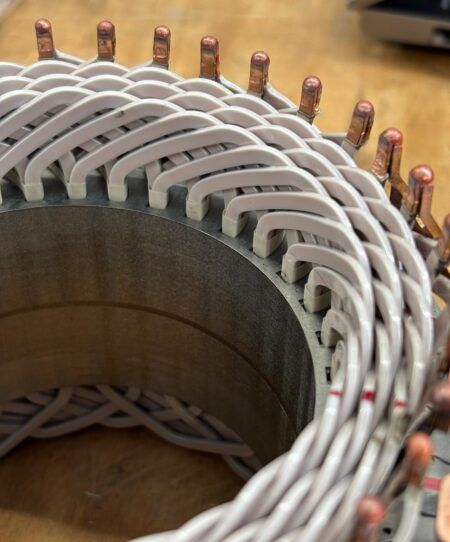

Aside from its rotational performance of 1.8 million dmN (a 28.5% increase), the new bearing features the world’s first cage to leverage the benefits of topology optimization. By using this process, it was possible to optimize the material layout inside the design space with the goal of maximizing product performance.

For the new bearing, topology optimization helped to maximize strength and minimize weight by eliminating parts that did not contribute to cage durability or rigidity, while also serving to derive the optimal cage shape for high-speed rotation. The development time of the cage was very short by using leading-edge simulation technology to verify cage performance and production considerations.

The cage makes use of a new high-rigidity resin material that is more effective at suppressing deformation during high-speed rotation than conventional materials. As a further point of note, NSK fills the bearing with a proprietary grease that reduces lubricant churning resistance and any subsequent heat generation, prolonging both grease and bearing life, and reducing the risk of seizure. It is the combination of special NSK grease and newly developed cage that enables this high-performance deep groove ball bearing to operate at over 1.8 million dmN.

Having a bearing of this capability enables customers to develop and implement electric motors that operate at significantly higher speeds. Higher motor output contributes to greater efficiency (reducing power consumption per unit distance), extended vehicle range and enhanced user comfort. Higher speeds also facilitate the utilization of smaller motors, thus reducing vehicle weight and increasing the amount of space available for other components, more battery cells, or a larger vehicle interior.