Any electric powertrain component starts as a concept on the drawing board and makes its way through a design and simulation process into reality. To evaluate the reality against the design and simulations, comprehensive testing and measurements are vital. To that end, test engineers need to carefully consider the complete measurement setup from the selection of sensors for the acquisition of different signals to the acquisition device, and the analysis of the acquired data in software.

A new integrated hardware and software tool developed by Dewesoft has been designed to help provide engineers with precise analysis.

In an electric vehicle (EV) the power originates from the battery which supplies an inverter with the high voltage direct current. To power the electric motor, the direct current is normally inverted to symmetrically displaced, three alternating phase currents via an inverter.

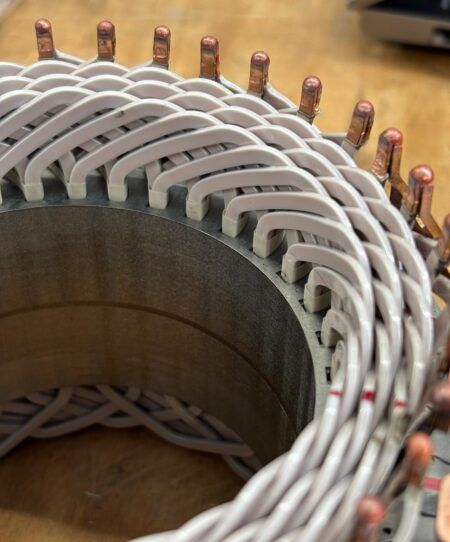

Developing more efficient inverters requires innovation and optimization on multiple fronts. One is ever higher inverter switching frequencies. The emerging technology of silicon-carbide (SiC) field-effect transistors (MOSFETs) enables the manufacturers to push towards the 100 kHz range. Higher switching frequencies enable the reduced size of passive components – such as inductors and capacitors – and consequently reduce the weight of the inverter. Switching frequencies above the audio range also mean reduced airborne noise caused by the vibrations excited by the electromagnetic force. On the other hand, higher switching frequencies intensify unwanted phenomena such as capacitive bearing currents, which also need to be measured and analyzed.

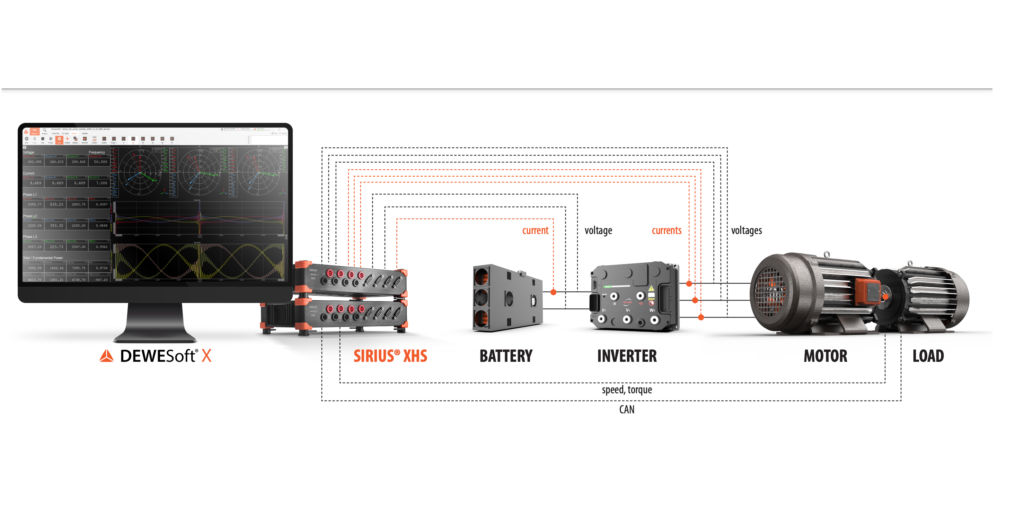

In total, the measurement conditions call for a measurement solution with a bandwidth that will not attenuate any interesting phenomena that may occur: a sampling rate that will accurately capture fast transients and ten or more harmonics of the inverter switching frequency, and sensing capability that will safely and accurately measure leakage as well as peak currents. Lastly, data needs to be analyzed in real-time as well as be available for post-analysis. Dewesoft has developed seamlessly integrated hardware and software tools that answer all these measurement requirements.

Dewesoft’s latest development, the Sirius XHS, features eight channels – four high-voltage, and four low-voltage – with sampling rates up to 15 MSPS, a bandwidth of 5MHz, and a dynamic range of 150 dB in the world’s smallest power analyzer. The device offers channel-to-channel and channel-to-ground isolation on all channels with CAT III 600V safety rating on high-voltage channels and accuracy up to 0.03%. Excitation on low-voltage channels enables users to directly connect and power certain current transducers. Transducers that require more power, can be supplied via an additional power supply unit. A modular design also enables the ability to stack and synchronize multiple Sirius slices for demanding measurement tasks.

The DewesoftX software enables the recording of raw data as well as real-time analysis with a power analysis module that outputs over 150 different measurements ranging from basic active and reactive power parameters to overlapping period values of fundamental harmonics and period symmetrical components. Customizable controls allow visualizations in time, frequency, and polar domains. To perform the real-time power analysis at high sampling rates offered by the Sirius XHS, the GPU (Graphics Processing Unit) adds processing power. The architecture of the GPU enables massive parallelization of the computation load and can perform certain tasks orders of magnitudes faster than the CPU. As a result, users can simultaneously run even three power modules at a high sampling rate on a mid-range laptop with a GPU.