The importance of industry-standard test methods in specifying cell-to-cell barrier performance

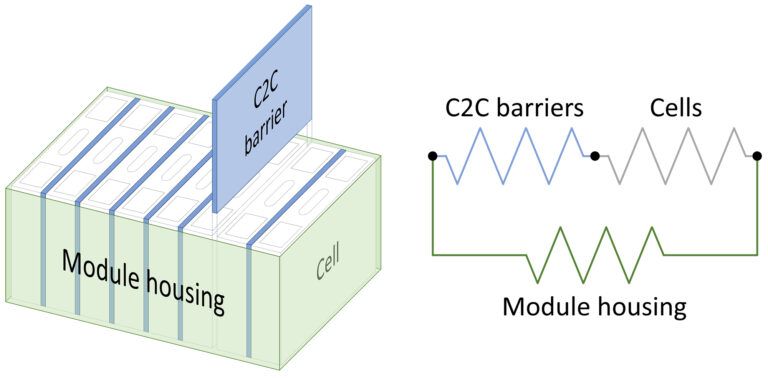

In the world of pouch and prismatic cells, the mechanical design of battery modules is a subtle art. Cells often have limits on their minimum and maximum cell-face pressures, and even within those limits, there are often narrower, preferred ranges that prolong their state of health. The module designer’s challenge is that cell-face pressure is not just an arbitrarily applied boundary condition. Rather, it is a negotiated settlement amongst all the elastic elements within a module: cells, cell-to-cell (C2C) barriers, and the module itself (Figure 1). While the module assembly process helps establish the initial conditions of this negotiation, cell-face pressure evolves as the cells breathe and swell throughout their lifecycle.

The system’s mechanical behavior is usually fine-tuned using the design of the C2C barrier. This function has historically been provided by compression pads, often polyurethane or silicone foams. Recently, however, the need to slow or prevent thermal propagation (i.e., when a thermal runaway event spreads from one cell to its neighbors) has required that compression pads also perform double-duty as high-temperature thermal insulation. Thus, the C2C barrier was born, fulfilling both mechanical and thermal functions.

Cell-to-cell barriers help preserve battery health and provide the first line of defense in a thermal runaway event. While C2C barriers are crucial to a battery’s safety and performance, engineers face a challenge when evaluating potential solutions. The combined functionality of C2C barriers is so new that standardized test procedures have yet to emerge. The CSA Group has convened working group C22.2 No. 350 – Thermal Barrier Safety for Batteries and Energy Storage Systems – to help address this need. Participation is encouraged for buyers and sellers of thermal barrier materials, as well as test laboratories and other interested parties.

To better understand the industry’s need to develop testing standards, the following are current methods to examine the performance of C2C barrier materials.

For thermal performance, the gold standard is the mini-module test, in which one cell is driven into thermal runaway while its neighbor – separated by a C2C barrier – is monitored for its own thermal stability. However, not all laboratories are equipped to conduct such tests, so a surrogate method is often used. In this surrogate method, a C2C barrier is sandwiched between two platens, one of which is heated to the anticipated exposure temperature (e.g., 800°C). The temperature of the cold-face platen is then monitored, and the pass/fail criteria is to stay below a certain temperature after a certain time. Heated-plated test results vary widely because of the lack of standardized equipment and procedures. For example, some conduct platen testing under constant pressure, some under constant displacement; some use active cooling on the cold-face platen, while others use an inert dummy block; and sample sizes vary from lab to lab.

Mechanically, there is a need to characterize the stress-strain behavior at various stages over the module’s life. Beginning of life (BOL) is straightforward, as materials are new and part geometries – especially thickness – have yet to change. At the end of life (EOL), however, the effects of creep, fatigue, and compression set have typically changed the behavior of the C2C barrier. Assessing EOL performance is an area where standardized test procedures would greatly assist the industry, reducing duplicated effort, and streamlining the design and procurement processes.

Effective C2C barriers are crucial to the adoption of battery electric vehicles. Those involved in designing modules or packs should consider joining CSA’s working group to support the next generation of EVs.