Saietta, a specialist in e-mobility propulsion, has released a video showcasing its new Axial Flux Technology electric motor, which it claims will bring a step change in motor performance and accessibility for electric vehicles.

As vehicle manufacturers scramble to decarbonize and develop new electric vehicles (EVs), there is a significant and growing demand to make EV technology more accessible. Affordable electric propulsion and battery systems are key to reducing EV cost and enabling widespread adoption. This is an essential step for many emerging economies and cities that are gripped by chronic air pollution, especially in Asia.

Within these regions, the most common forms of transport are lightweight two-, three- and four-wheeled vehicles, which are used by millions of people daily. Following extensive market research, Saietta believes the fastest way to tackle the emissions crisis is to provide viable electric motor alternatives for small, internal combustion engine powered vehicles.

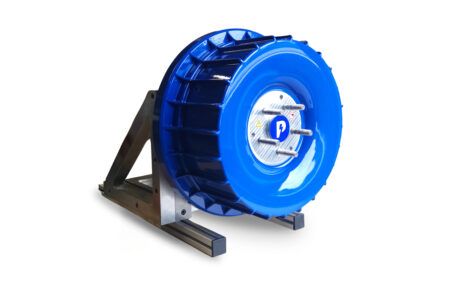

With an intimate understanding of the challenges currently facing EV manufacturers, Saietta has addressed industry requirements with its AFT series of electric motors. Heralded as an enabler of widespread electrification, its first AFT e-motors – the AFT 140 and AFT 110 – are designed to offer greater efficiency while providing a reliable, cost-effective propulsion solution with zero tailpipe emissions. Their high urban duty cycle efficiency reduces the battery capacity and hence cost of the battery pack required for a given range.

For their size and weight, the AFT motors provide substantial torque and can sustain high power output through the addition of a simple water-cooling system. Perhaps most importantly, they have been specifically designed for highly automated production to further drive down cost, ensuring the perfect combination of practical performance at a price point that is viable for the target markets.

Saietta’s rigorous testing program saw a fleet of two-, three- and four-wheeled demonstrator vehicles retrofitted with the AFT. The scooters, motorcycles, rickshaws, last-mile delivery vehicles and micro-cars have all helped to highlight the versatility and reliability of the AFT e-motor. Following rigorous testing on the 20 miles of private roads at Saietta’s location in Oxfordshire, the AFT has been fully optimized for the lightweight EV spectrum.

Another pain point for EV manufacturers is motor and controller integration. Saietta addressed this by developing the AFT to be integrated with a broad range of off-the-shelf controllers. In fact, every vehicle in the AFT test fleet uses a different controller, further demonstrating the adaptability of the e-motor. A flexible in-house controller is also under development.

With the AFT now in low volume production, Saietta’s engineering team is finalizing the development of a new, high-voltage variant intended for high-performance vehicles.

Wicher Kist, chief executive of Saietta Group plc, commented: “Saietta is intent on helping the world go further, accelerating toward a cleaner, more sustainable and prosperous future. Through widespread EV adoption and emissions reduction, cities around the world will be radically transformed, from Jakarta to Mumbai, Shanghai to Cairo.

“We recognize just how critical accessible electrification for lightweight vehicles will be in achieving these aims and we are addressing key market challenges by developing new, leading-edge electric propulsion technologies. Our AFT motors are compact and light while delivering high torque and efficiency at low voltage. This will enable vehicle manufacturers to reduce the required battery size for a given range and, in turn, use less rare materials in their construction.

“Specifically designed for highly automated production, our AFT motors are intended to make lightweight EV adoption more viable by reducing total vehicle cost. They are incredibly versatile and easily integrated into vehicle platforms. By providing the e-mobility solutions of today, we are building momentum towards a more sustainable, electrified tomorrow.”